December 19, 2025

Why Liquid Cooling Is the Best Choice for High-Efficiency and High-ROI C&I Energy Storage

Share my #SolaXStory

Liquid Cooling vs. Air Cooling: Performance Comparison for C&I Energy Storage

The energy storage landscape is consolidating around proven technologies. The International Energy Agency (IEA) reports that the dominance is fueled by a massive 90% decline in lithium-ion battery prices since 2010(IEA: Batteries and Secure Energy Transitions – Executive Summary). This table compares key performance metrics between liquid cooling and air cooling systems in commercial and industrial energy storage applications, helping readers understand why liquid cooling offers superior efficiency and ROI.

Performance Metric | Liquid Cooling | Air Cooling | Advantage |

Operating Temperature Range | 15°C - 35°C (optimal) | 20°C - 45°C (variable) | Liquid Cooling: ±5°C precision |

Cooling Efficiency | 95-98% | 80-85% | Liquid Cooling: +13-15% |

Energy Consumption for Cooling | 2-3% of system capacity | 5-8% of system capacity | Liquid Cooling: 50-60% less |

Battery Lifespan Extension | Up to 20% longer | Baseline | Liquid Cooling: Extended cycles |

System Energy Density | Higher (compact design) | Lower (requires more space) | Liquid Cooling: 30-40% smaller footprint |

Noise Level | <50 dB | 60-75 dB | Liquid Cooling: Quieter operation |

Maintenance Frequency | Annual | Quarterly | Liquid Cooling: Lower OPEX |

In the commercial and industrial (C&I) sector, energy costs and operational efficiency are critical to business success. The challenges are driving a growing need for advanced energy storage solutions that can reduce costs, stabilize power supply, and maximize the financial return of energy assets. C&I energy storage is no longer a niche market; it is an essential grid resource. Wood Mackenzie tracked a record-breaking 106 GW of new energy storage capacity in 2025, a 43% increase over the previous year(Wood Mackenzie: Global Energy Storage Market Surpasses 100 GW Milestone). As installations scale, high-efficiency solutions like the SolaX ESS-TRENE ensure that commercial users can capture the maximum financial benefit of this global energy transition.

One solution that stands out for solving these pain points is the liquid cooling system, especially when paired with modern energy storage solutions like the SolaX ESS‑TRENE Liquid Cooling System. In this article, we explore why liquid cooling technology is the ideal choice for C&I applications and how it paves the way to maximum efficiency and shortest ROI.

The Core Pain Points in C&I Energy Management

Before understanding why liquid cooling is a game‑changer, it’s important to frame the energy challenges that C&I customers face:

A. High Operating Costs (Especially Demand Charges)

For many businesses, electricity bills are dominated by demand charges — fees based not just on how much energy is consumed, but how much is used at peak times. In fact, demand charges can account for a large portion of monthly utility costs, especially for facilities with high power draw during certain hours of the day.

These peak demand fees often make energy bills unpredictable, putting significant pressure on business finances. Traditional grid supply alone cannot effectively mitigate these costs.

B. ROI Uncertainty for Energy Infrastructure Investments

C&I energy storage systems typically require significant upfront investment. While the long‑term benefits can be substantial, businesses often struggle to calculate and justify ROI due to fluctuating energy prices, complex billing structures, and variable usage patterns.

Because of this uncertainty, many companies hesitate to invest in energy storage solutions or miss out on the full potential value these systems can deliver.

C. Energy Supply Stability and Operational Efficiency

In industries like manufacturing, logistics, data centers, and commercial buildings, any power instability can cause costly disruptions. Voltage dips, brownouts, or sudden outages can interrupt operations, affect sensitive equipment, and reduce productivity.

Businesses therefore, need energy solutions capable of reliable, consistent performance — not just cost savings.

How Liquid Cooling Enhances C&I Energy Storage Efficiency

To address these pain points, energy storage systems must operate at high efficiency, reliably handle thermal stress, and support advanced energy management strategies — this is where liquid cooling technology shines.

A. Superior Thermal Management for High Performance

Liquid cooling systems use fluid circulation to manage heat buildup across battery cells more effectively than air cooling, especially in high-energy-density environments.

For instance, the SolaX ESS‑TRENE Liquid Cooling System maintains temperature differences between cells within a tight band (≤ 3°C), ensuring optimal performance and reducing thermal stress on the battery modules.

This advanced cooling enables batteries to operate more efficiently under heavy loads and frequent charge/discharge cycles — a common requirement in peak shaving and energy optimization strategies.

B. Longer Lifespan and Greater Reliability

By maintaining cell temperatures under ideal ranges, liquid cooling ensures the long-term health of the robust 314 Ah LFP battery, chemistry, directly translating. Less frequent replacements and lower maintenance costs directly contribute to better long‑term ROI. Thermal precision is the ultimate defense against capacity loss. Industry benchmarks from Lazard indicate that oversizing battery capacity to offset future degradation is now a standard strategic trend to protect a project's residual value(Lazard's LCOE+ June 2024 Report).

Additionally, systems like ESS‑TRENE incorporate multi‑layer safety designs, including four‑level fire protection and enhanced fault detection systems, making them both safe and reliable for demanding industrial environments.

Peak Shaving and Demand Response: The Pathway to Cost Savings

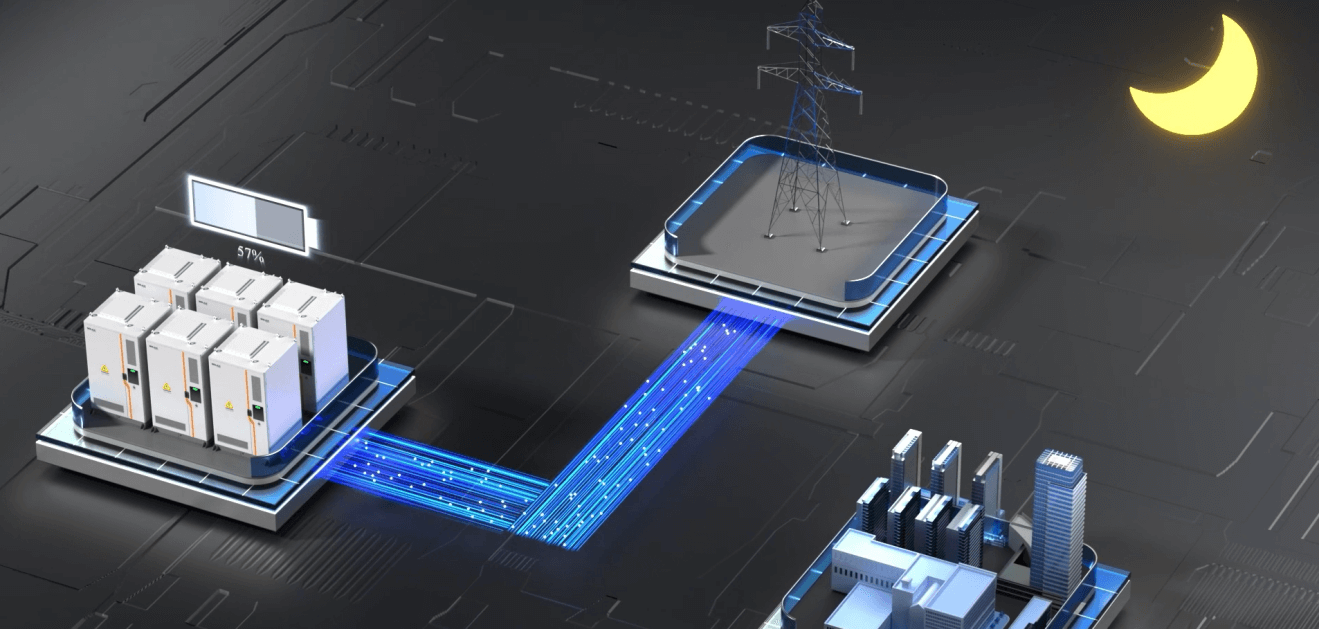

One of the most effective ways for businesses to reduce energy costs and improve ROI is through peak shaving — storing energy during low‑cost periods and discharging it when demand charges are high.

A. What is Demand Response?

Demand response (DR) programs incentivize businesses to adjust their energy usage during peak grid demand. When electricity demand threatens grid stability, utilities ask participants to lower their consumption or supply stored energy. In return, businesses receive financial rewards.

With C&I battery storage systems, companies can store energy during off‑peak times and discharge it during these peak demand events, reducing strain on the grid and earning demand response incentives.

Participation in demand response not only improves grid reliability but also lowers operational energy costs, helping businesses offset the total cost of their energy storage systems.

B. Peak Shaving and High ROI Synergy

Peak shaving directly reduces demand charges, which can be some of the largest components of a business’s energy bill. By implementing an energy storage system with liquid cooling, companies can ensure high efficiency and reliability in energy discharge, maximizing the value they receive from each stored kilowatt‑hour.

Furthermore, with intelligent energy management — such as AI‑driven scheduling and automated responses — systems like ESS‑TRENE optimize when to charge and discharge, boosting operational efficiency while minimizing manual intervention.

The Financial Benefits of C&I Battery Storage with Liquid Cooling

Since the renewables stand out as both the lowest-cost and quickest-to-deploy generation resource(Lazard Levelized Cost of Storage (LCOS) 2024). This makes SolaX's integrated EMS and liquid cooling systems—which reduce cooling-related energy waste—the most significant levers for improving a project's financial bottom line.

Let's break down how liquid cooling supports a shorter ROI timeline by driving multiple financial benefits:

A. Reduced Demand Charges

With peak shaving and optimized discharge scheduling, businesses can significantly reduce the portion of their energy bill tied to demand charges — often the largest cost driver in C&I electricity bills.

Liquid cooling ensures that this peak shaving happens efficiently and reliably, even under high demand.

B. Incentive Participation and Revenue Opportunities

Storage systems that participate in demand response or grid service programs can generate additional revenue or bill credits. Utilities and grid operators often reward customers who help balance supply and demand — another contributor to improved ROI.

C. Lower Operational and Maintenance Costs

Optimized thermal management means batteries age more slowly and require fewer replacements or interventions. Long‑term operational costs drop, reducing total cost of ownership and improving ROI.

D. Enhanced Use of Solar Energy Through Storage

Combining C&I solar installations with battery storage ensures that excess solar energy generated during daylight hours gets stored and used later, rather than wasted or sold back at low rates. In doing so, businesses capture more value from their solar assets and further reduce grid dependence.

SolaX C&I Solutions: Built for Maximum Efficiency and Flexibility

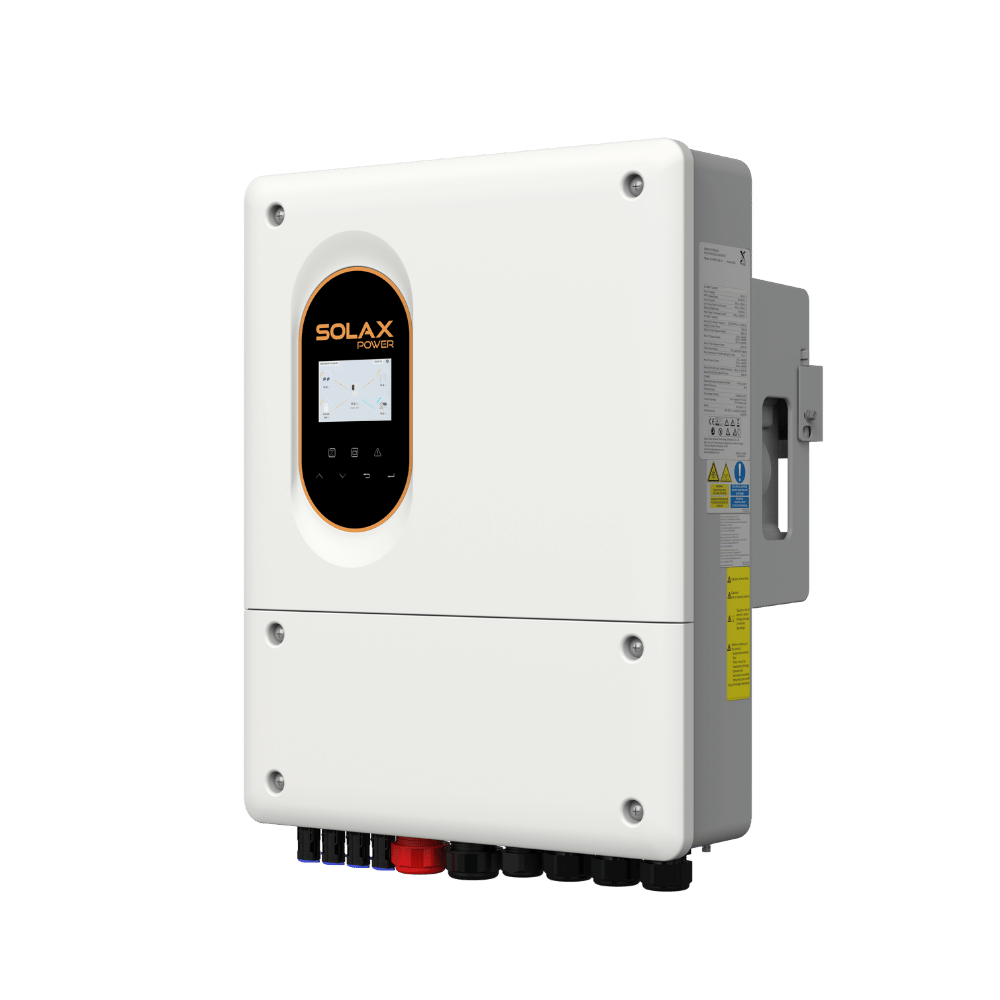

The SolaX ESS‑TRENE Liquid Cooling System exemplifies how modern liquid‑cooled storage solutions address the unique needs of C&I applications:

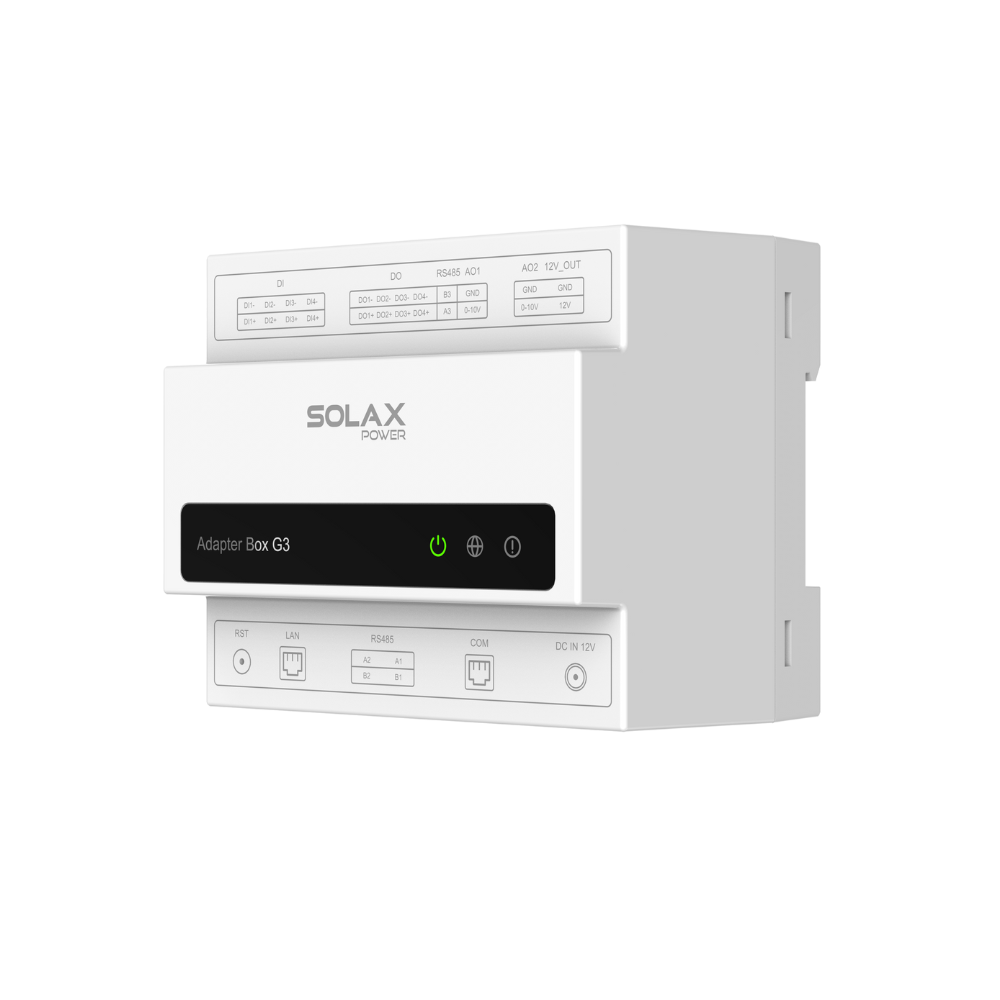

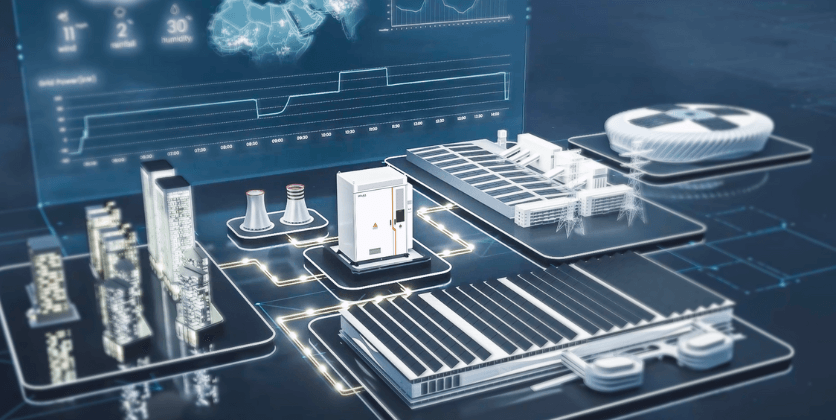

A. Intelligent Energy and Safety Management

ESS‑TRENE includes integrated BMS (Battery Management System) and EMS (Energy Management System) capabilities, allowing for advanced cloud‑based control through EMS1000 PRO with real‑time monitoring and remote management — ensuring operational efficiency and data visibility.

AI‑powered energy optimization features help reduce operational costs and improve dispatch decisions for peak shaving and demand response participation.

B. Scalable and Flexible Design

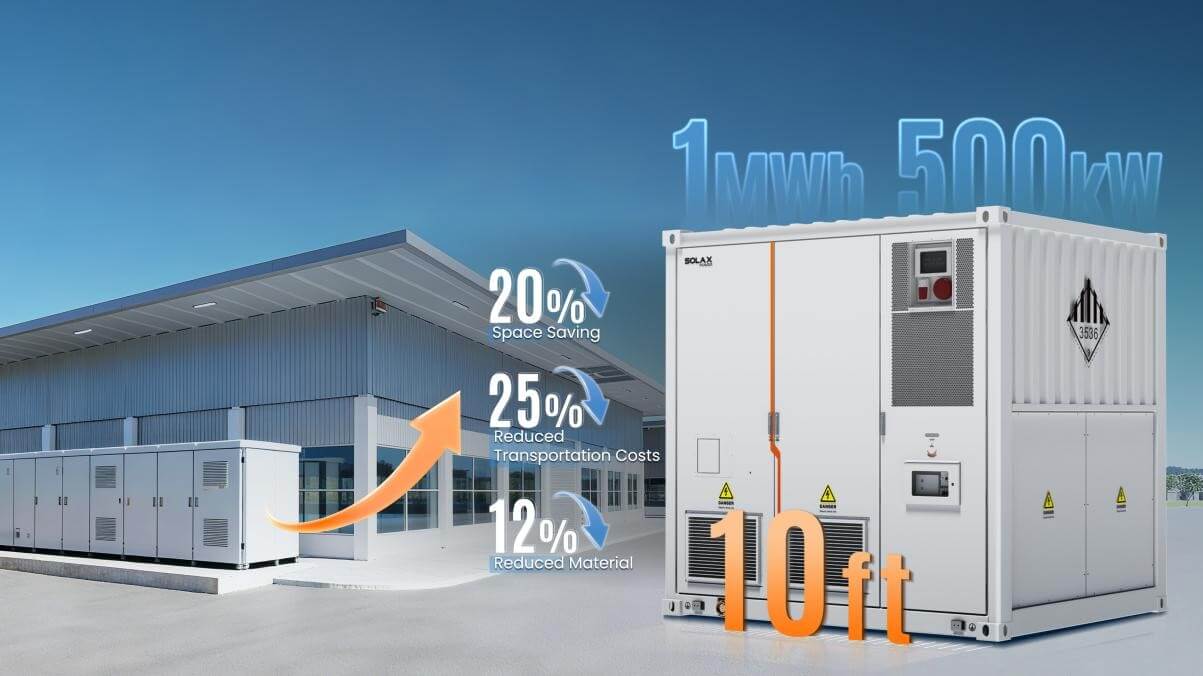

The core ESS-TRENE Liquid Cooling unit is a powerful asset, featuring a 261 kWh stand-alone capacity and 125 kW output (with 137.5 kW peak), which is readily expandable to multiple megawatt-hours, ensuring the system size perfectly matches the energy demand required for maximum ROI.

Whether the goal is peak shaving, backup power, or grid participation, the system adapts to energy needs and supports both grid‑connected and off‑grid applications.

C. Strong Safety and Operational Resilience

Multi‑layer fire protection and robust IP ratings for batteries and inverters ensure resilient performance in diverse environments — specifically IP67 for the battery, IP66 for the inverter, and IP55 for the cabinet—ensure resilient performance and safety compliance across diverse industrial environments.

Conclusion: A Strategic Choice for C&I Energy Leaders

For commercial and industrial energy decision‑makers, choosing the right energy storage solution can determine whether an energy strategy delivers strong financial returns or becomes an underperforming investment.2

Liquid cooling systems have a clear edge in C&I applications because they:

Improve thermal efficiency, enabling higher system performance and longevity.

Enable reliable peak shaving and demand response participation, driving meaningful cost savings.

Support enhanced solar utilization and reduced grid dependence.

Lower long‑term operational and maintenance costs that further accelerate ROI.

By addressing the core pain points of energy cost, reliability, and ROI uncertainty, liquid cooling systems like the SolaX ESS‑TRENE Liquid Cooling System empower businesses to maximize energy efficiency and financial return — making them the best choice for C&I energy storage applications today.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms