January 04, 2026

EPC Guide: Utility Scale BESS for Grid Energy Storage

Share my #SolaXStory

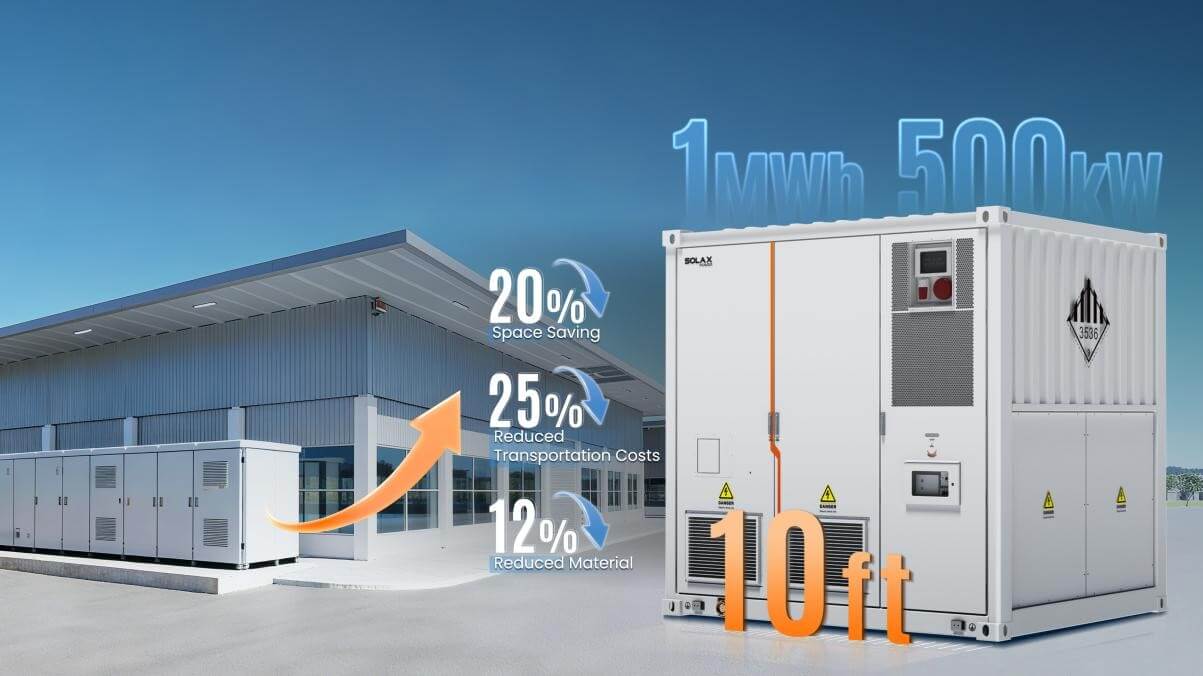

Containerized battery energy storage solutions (BESS) are fundamentally changing the EPC process for utility scale battery storage. Instead of field assembly and on-site debugging, EPC teams can now use standardized, containerized blocks that arrive ready for placement, connection, and commissioning. This approach reduces on-site labor and schedule risks, especially when utility scale solar power is involved and interconnection timelines are strict.

This ultimate guide offers an EPC playbook on how to design, install, and optimize these containerized battery storage utility scale projects. SolaX Power's utility ESS platform supports this approach by emphasizing factory pre-assembly and modular scaling. These concepts align with SolaX Utility Scale ESS Solutions. The goal is simple: turn containerized blocks into a disciplined and reliable execution system.

Application Module 1: Use Case and Sizing

Sizing decisions are vital: they either ensure repeatable success or bake in years of operational difficulty. EPC teams must map value streams (what the system should do) alongside constraints (what the system is allowed to do). For instance, a co-located utility scale solar power plant may aim to shift midday production to evening peaks. However, the interconnection agreement might limit export or impose ramp-rate requirements. The output profiles and curtailment patterns of Photovoltaic (PV) Systems also influence the optimal charging strategy. Economics are no longer a barrier to utility-scale deployment. BloombergNEF reports that the global benchmark LCOE for battery storage projects fell by a third in 2024 to $104/MWh(BloombergNEF: Global Cost of Renewables to Continue Falling in 2025). This price threshold makes containerized solutions like SolaX ORI increasingly competitive against traditional peaking plants.

Practical Sizing Workflow

A practical workflow for sizing includes five key steps:

Define services and priority order. Decide whether arbitrage, reliability, or reserve provision is the primary driver. This determination sets the cycling intensity and thermal stress.

Set power (MW) target from grid services. High-power, short-duration systems behave differently than long-duration systems in both protection and thermal design.

Set energy (MWh) and duration. Base this on the variable electricity tariff or the necessary peak window.

Validate against interconnection. Confirm MV level, fault current contribution, protection coordination, and any operational constraints.

Stress-test with scenarios. Run checks against conservative market spreads, aggressive cycling, and high-ambient-temperature operation.

Standardization vs. Customization

While air cooling was once the standard, the industry is rapidly pivoting toward liquid cooling. BIS Research projects the liquid cooling market for stationary BESS will grow at a CAGR of 21.55% through 2033, driven by its ability to eliminate hot spots and reduce thermal runaway risks(Market Research Blog: Liquid Cooling Powering the Future of BESS). SolaX's ORI series utilizes this advanced thermal management to ensure cell consistency and extended lifespan.

The SolaX ORI is an example of a factory-integrated system designed for practical replication and faster delivery. ORI combines a 2.5 MW PCS with a 5.015 MWh battery container. This pre-engineered, containerized form factor uses LFP cells and liquid cooling to support stable operation under demanding duty cycles.

Application Module 2: Containerized System Architecture

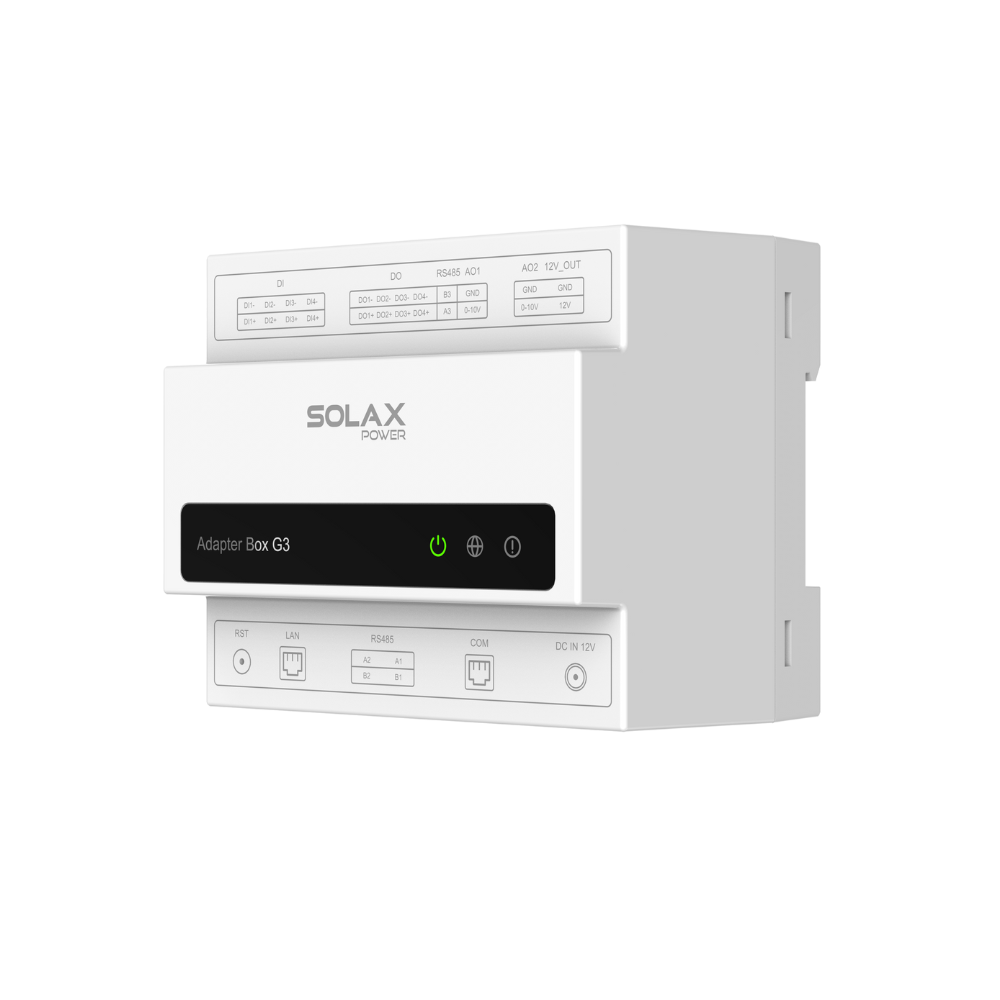

Although a containerized architecture looks “simple” on a one-line diagram, EPC performance depends on clear separation of PCS, BMS, and EMS duties. These layers form a hierarchy of decisions:

BMS (Battery Management System): Manages cell safety, monitoring voltage/temperature, and protection triggers.

PCS (Power Conversion System): Handles DC/AC conversion, reactive power, and fast power control.

EMS (Energy Management System): Manages dispatch logic, optimization, market participation, and coordination with resources like PV.

Commissioning issues frequently arise when these layers conflict. For example, the EMS requests power, but the BMS limits output due to thermal conditions. Containerized systems reduce this risk by validating internal interactions at the factory, allowing EPC teams to focus on the plant interface.

Understanding PCS Modular Design

Specifications sometimes refer to blocks like a 350 kW inverter class, especially when scaling involves paralleling multiple PCS strings. The key EPC consideration is what this means for redundancy and fault isolation. While more smaller conversion strings can improve availability, they might complicate communications and protection testing.

The SolaX ORI’s PCS is described as a “high-performance string PCS”. This design uses repeated sub-blocks, such as 215 kW × 12 DC-rated power units feeding a 2,500 kVA AC output. This modular approach offers the benefits of fault isolation and a clear path for scaling inverter storage.

Designing for Interoperability and Reliability

Interoperability is mainly a controls and communications challenge. Your goal is to make inverter storage behave like a predictable plant resource for SCADA and the grid operator. This requires deterministic time synchronization, consistent naming and signal mapping, and validated fallback modes when communications fail. Standards like NIST’s work on IEEE 1588 timing profiles remind us that reliable time synchronization is necessary for correlating events across controls.

To streamline EPC work, SolaX Utility Scale ESS Solutions emphasizes comprehensive monitoring, automated fault isolation, and multi-layer electrical protection. These elements are most valuable when they reduce the number of custom logic patches an EPC needs to create during commissioning.

Application Module 3: Site Design and Civil Works

The Electric Power Research Institute (EPRI) concludes that effective site design, including drainage and proper routing, plays a critical role in prolonging the lifespan and reducing the maintenance needs of large-scale energy storage systems[EPRI]. Civil work is critical because site design determines whether the container is serviceable, safe, and maintainable for years. The goal is to design a site that supports fast installation now and easy maintenance later.

Layout, Clearances, and Access

Start with access and clearances. Define the crane plan, truck turning radius, and maintenance access corridors before foundations are poured. A frequent problem is placing utility scale battery storage containers too tightly to optimize land use. Restricted access leads to higher Mean Time to Repair (MTTR) and increases the loss of dispatch value.

Foundations, Routing, and Drainage

Cable routing must be treated as a key civil deliverable. Poor planning of trench depth, bend radius, and crossing management leads to late reroutes, change orders, and schedule slips. Drainage and water management are also vital. Standing water near container pads accelerates corrosion risk and complicates grounding integrity. If the system uses liquid cooling, the site layout must also ensure effective airflow and prevent heat recirculation.

Making Maintainability a Civil Requirement

A strong EPC checklist translates “maintainability” into measurable constraints. This includes defining minimum clearance for service doors, ensuring safe working areas for technicians, and planning staging zones for component replacement. SolaX ORI aims for rapid maintenance, noting “1-hour part replacement” as a design goal. The EPC team’s job is to ensure the site preparation supports this advantage by not blocking access or skipping laydown space.

Application Module 4: Electrical Integration and Grid Compliance

Electrical integration is where EPC execution meets utility expectations. Even if a containerized utility scale battery storage system is tested internally, interconnection is always site-specific. Your design must align with the MV system, protection philosophy, grounding approach, and operational requirements, especially when co-located with utility solar or utility solar power plants. Reliability depends on more than just hardware; it requires sub-microsecond synchronization. According to NIST, precision timing (IEEE 1588) is now critical for real-time control, as poor synchronization can cause out-of-control situations and equipment downtime(NIST Technical Series: Timing Challenges in the Smart Grid).

MV, Protection, and Grounding Coordination

Typical MV scope includes step-up transformers, switchgear, protection relays, and the grounding grid. The coordination challenge arises because an ESS can be both a source and a sink, with fast power electronics that respond differently than rotating machines. This behavior affects relay settings, grounding strategy, and harmonic compliance. A good practice is to finalize a “protection settings baseline” early. Late changes to protection logic are a major cause of re-testing and commissioning delay.

Coordinating with Solar and Hybrid Sites

When combining ESS with Photovoltaic (PV) Systems, coordination questions arise. Does the plant controller prioritize PV export, ESS charging, or grid-support functions? How is curtailment handled? For behind-the-meter or hybrid sites, Net Metering rules (if applicable) influence the design of export limits and metering configurations. Commercial rules often create specific technical requirements, such as metering points and export control loops.

Communications and VPP Readiness

Commissioning frequently stalls due to communications problems rather than electrical faults. Under-spec’d networks, missing time synchronization, inconsistent network planning, or unclear signal lists can make a “connected” system impossible to operate reliably. This is critical if the project intends to participate in vpp electricity aggregation. The SolaX utility platform emphasizes factory pre-assembly to achieve fast grid commissioning. This requires the EPC’s MV and communications design to be equally standardized and validated early.

Application Module 5: Commissioning, O&M, and Optimization

Commissioning is the handoff from EPC delivery to multi-year performance. The best EPC teams treat commissioning as a structured verification of the entire lifecycle plan. Future-proofing means preparing for the VPP boom. The Virtual Power Plant market is expected to grow from USD 3.94 billion in 2025 to USD 5.01 billion in 2026 and is forecast to reach USD 16.61 billion by 2031 at 27.08% CAGR over 2026-2031(Mordor Intelligence: Virtual Power Plant Market Size & Share 2030). SolaX's platform is designed to meet these orchestration demands, allowing EPCs to bid battery discharge into multiple markets simultaneously.

Acceptance Testing Traceability

A comprehensive acceptance approach for battery energy storage solutions typically includes insulation resistance tests, functional verification of protection shutdowns, SCADA point-to-point testing, and thermal performance checks. It also covers charge/discharge performance tests (power and efficiency). The core principle is traceability: every acceptance test must link back to a requirement, such as an interconnection agreement, safety standard, or performance guarantee.

Enabling Predictive Maintenance

Predictive Maintenance relies on high data quality and strong anomaly detection logic. It starts with consistent telemetry: temperatures, voltages, alarms, and event logs. Advanced detection flags minor changes, such as a cooling loop consuming more auxiliary power or widening battery temperature spreads. EPCs must design for data quality by ensuring telemetry is complete, time-synchronized, and consistently mapped. Designs that support monitoring, safe access, and disciplined maintenance reduce long-term risk.

Optimization and VPP Readiness

If your owner plans to enroll assets in a vpp electricity program, design for it early. VPP participation demands stable telemetry, secure command pathways, and well-defined operational constraints (like SOC limits and availability windows). Many projects attempt to add VPP capability later and discover that the original network design was not suitable. Designing a clean controls stack now keeps future options open, especially as the inverter storage market evolves.

Selection and Decision Guide

Choosing containerized battery energy storage solutions means matching the project intent to a scalable, repeatable block strategy.

Matching Power and Duration to Needs

The power rating determines which grid services can be provided. Duration must align with the operational plan. A longer duration increases the footprint and auxiliary loads. EPC teams should use the variable electricity tariff history and dispatch plan to set a “minimum viable duration” and validate it using scenario analysis.

Controls, Safety, and Standardization

A containerized system’s value relies heavily on its controllability. If market dispatch is needed, ensure EMS capabilities support the operational modes you will use. Safety is also an essential selection factor. Your choice should consider the safety architecture (detection, suppression, and emergency planning) alongside local code requirements. Standardization is key. Replicable container blocks (e.g., 2.5/5/7.5 MW class) reduce engineering time, but bespoke sizing might perfectly match capacity requirements.

Decision Guide for Containerized Utility Scale ESS Selection

Decision factor | What to ask | Best-fit approach | Trade-off |

Power block size | Do we want replication or bespoke sizing? | Replicable container blocks (2.5/5/7.5 MW class) | Slightly less“perfect fit” to each site |

Duration | What is the real peak window and cycling plan? | Size to tariff window + operational margin | Over-sizing increases footprint and OPEX |

Interconnection | What MV level and relay philosophy apply? | Lock interfaces early; design for testability | Early alignment takes more upfront coordination |

O&M model | Who owns maintenance, and how fast must repair be? | Remote monitoring + serviceable layout | Requires disciplined data and site access planning |

Best Practices and Pitfalls for Utility Scale BESS

Key Best Practices for EPC Teams

Standardize container block designs across projects. Reuse single-line diagrams, communications templates, and commissioning scripts to reduce engineering time.

Finalize protection settings and philosophies early to prevent late delays and “surprise trips”.

Design the site for maintenance, not just installation. Keep clear service corridors and preserve vehicle access.

Treat communications as a primary system. Specify network architecture, time sync, and cybersecurity requirements early.

Build an O&M data discipline from day one. Define clear workflows for alarm responses.

Common Pitfalls to Avoid

Ignoring thermal and airflow modeling. Thermal problems show up later as derates, accelerated degradation, and inconsistent availability.

Under-specifying communications and time synchronization. Without reliable time sync, root-cause analysis becomes guesswork.

Delaying utility studies and permits. Interconnection timelines can dominate the schedule.

Over-customizing the initial project. If this breaks repeatability, the main benefit of containerized delivery is lost.

Conclusion: Accelerating Grid Scale ESS Projects

Containerized battery energy storage solutions let EPC teams turn utility scale battery storage from a one-off build into a repeatable delivery system. The cost of utility-scale battery storage fell to USD 192/kWh in 2024—a 93% decline since 2010, according to IRENA. The core strategy is to standardize around well-defined blocks, lock interfaces early, and treat civil works and communications as first-class design deliverables.

When you size correctly, design for maintainability, and commission with traceable acceptance tests, you reduce schedule risk and improve long-term performance for grid scale energy storage projects. For teams ready to operationalize this approach, the next step is to match your site’s grid services and constraints to scalable container blocks and build a deployment playbook you can reuse across every new site, leveraging solutions like SolaX Utility Scale ESS Solutions.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms