January 28, 2026

The Ultimate Guide to Slash Commercial Electricity Bills Using Energy Storage

Share my #SolaXStory

Commercial electricity bills are rarely driven by a single number. Most facilities pay for:

(1) total energy consumed (kWh),

(2) the highest power drawn during key intervals (kW demand charges),

(3) a growing stack of riders tied to capacity, grid services, and time-based pricing.

That is why many sites with efficient lighting and HVAC upgrades still see stubborn bills: the peaks remain, the tariff windows stay expensive, and volatility keeps creeping in. As the National Renewable Energy Laboratory emphasizes in its long-term storage planning analyses, the economic viability of these systems depends heavily on precise performance assumptions regarding efficiency, lifetime, and O&M costs(NREL) .

For a solutions overview that ties PV, ESS, and EV charging into one ecosystem, start here.

Commercial Solar Power and Energy Storage Fundamentals

Commercial solar power economics in plain terms

A well-designed commercial solar system primarily reduces the kWh you buy during daylight hours. The value of those kWh depends on your tariff, export rules, and how closely solar production matches your load. Many commercial solar companies design systems to maximize annual generation, but bill reduction depends on coincidence: if your load peaks late afternoon and your PV peaks at noon, savings may be less than expected unless you add storage. In short, PV is your low-cost on-site supply, but storage is what turns that supply into a bill-control tool.

What a solar energy storage system actually does

A solar battery storage system is not just backup. In C&I, it is a controllable energy buffer that can charge from PV or the grid and discharge on command. That enables three money-saving moves:

(1) peak shaving to reduce demand charges,

(2) time-of-use arbitrage to exploit a variable electricity tariff,

(3) self-consumption to capture PV that would otherwise be curtailed or exported at low value.

A modern commercial energy storage system also needs safety layers, thermal management, and integration with monitoring so you can verify results month by month.

Peak Shaving and Demand Charge Control

Peak shaving is usually the fastest path to material savings because demand charges can dominate the bill for facilities with short, sharp peaks.

Think of a distribution warehouse where several HVAC compressors and a few dock door motors start in the same 15-minute interval, or a factory where a single process line ramps up while the rest of the site is already loaded.

The utility does not care that the peak lasted 12 minutes; you pay for the maximum. A commercial energy storage system can discharge precisely during those peak intervals so the meter never sees the spike.

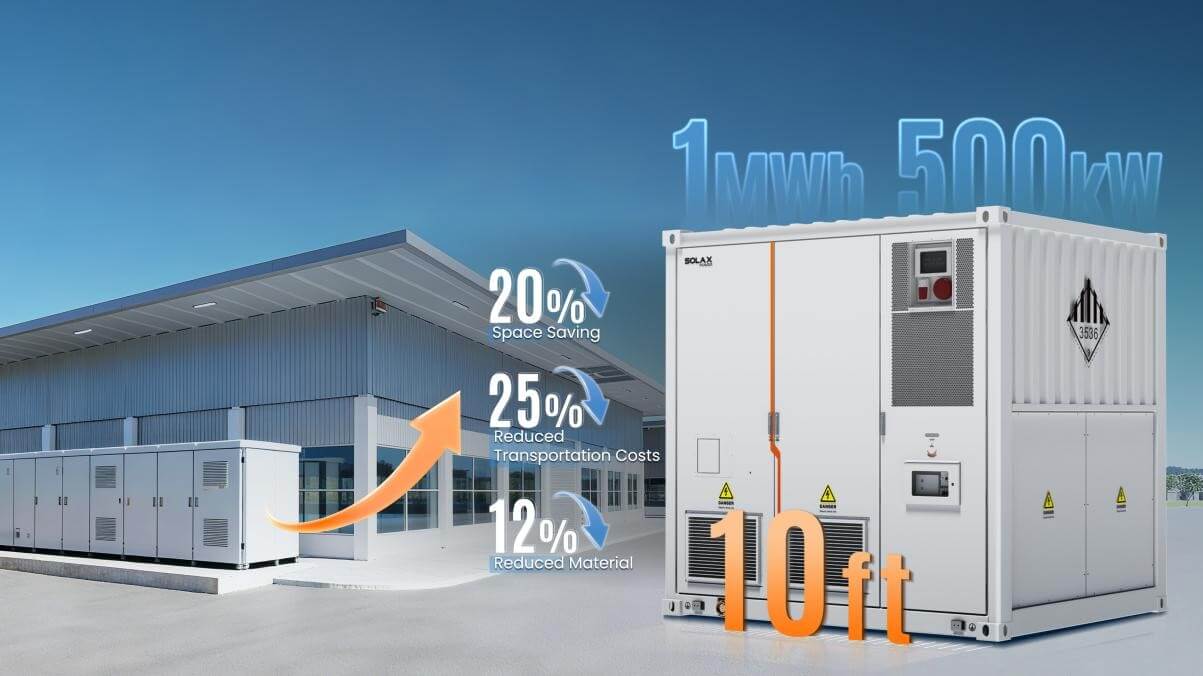

A practical product fit for this use case is an all-in-one C&I cabinet that integrates the battery, PCS, and thermal management so dispatch is predictable. SolaX ESS-TRENE Liquid Cooling is designed for C&I peak shaving with a 261 kWh stand-alone capacity and 125 kW output (peaking at 137.5 kW), using LFP cells and liquid thermal management with cell temperature differences controlled under 3 C.

Time-of-Use Arbitrage and Tariff Optimization

If your rate includes time-of-use pricing, critical peak events, or any variable electricity tariff structure, storage turns into a price-response engine. The principle is classic: charge when energy is cheap (or when PV is abundant) and discharge when energy is expensive.

SolaX systems emphasize smart scheduling and tariff-oriented control through monitoring. With an integrated cabinet like ESS-TRENE, you can combine a predictable PCS output with monitoring and automation so TOU schedules remain consistent.

If you need a more space-conscious variant, the ESS-TRENE Air Cooling configuration is presented as a 100 kW / 215 kWh option, using LFP cells (280 Ah), IP55 cabinet protection, and a modular architecture that supports three-phase unbalance output and 7x24h TOU scheduling. That makes it a practical tool for tariff optimization at sites where installation footprint and simplicity are priorities.

Solar Self-Consumption and Curtailment Reduction

Many commercial solar systems are designed around roof or ground constraints, but grid rules and tariff structures often limit exports. When export is capped or compensated poorly, midday PV can be curtailed or undervalued.

A solar energy storage system solves this by capturing PV at noon and discharging later when the site actually needs power. This increases the effective value of each kWh your PV produces and usually improves project economics compared with PV alone.

The first step is to quantify your self-consumption ratio: what portion of PV is used on-site in real time vs exported or curtailed. Then identify the mismatch.

In design terms, this is less about maximum battery power and more about usable energy and charge acceptance. If your PV surplus is steady for three hours, you want enough kWh to absorb it without hitting 100% SOC too early. If your surplus comes in pulses due to clouds, you want controls that respond quickly and do not oscillate. The result should be a flatter net load curve from the grid and fewer instances of export clipping.

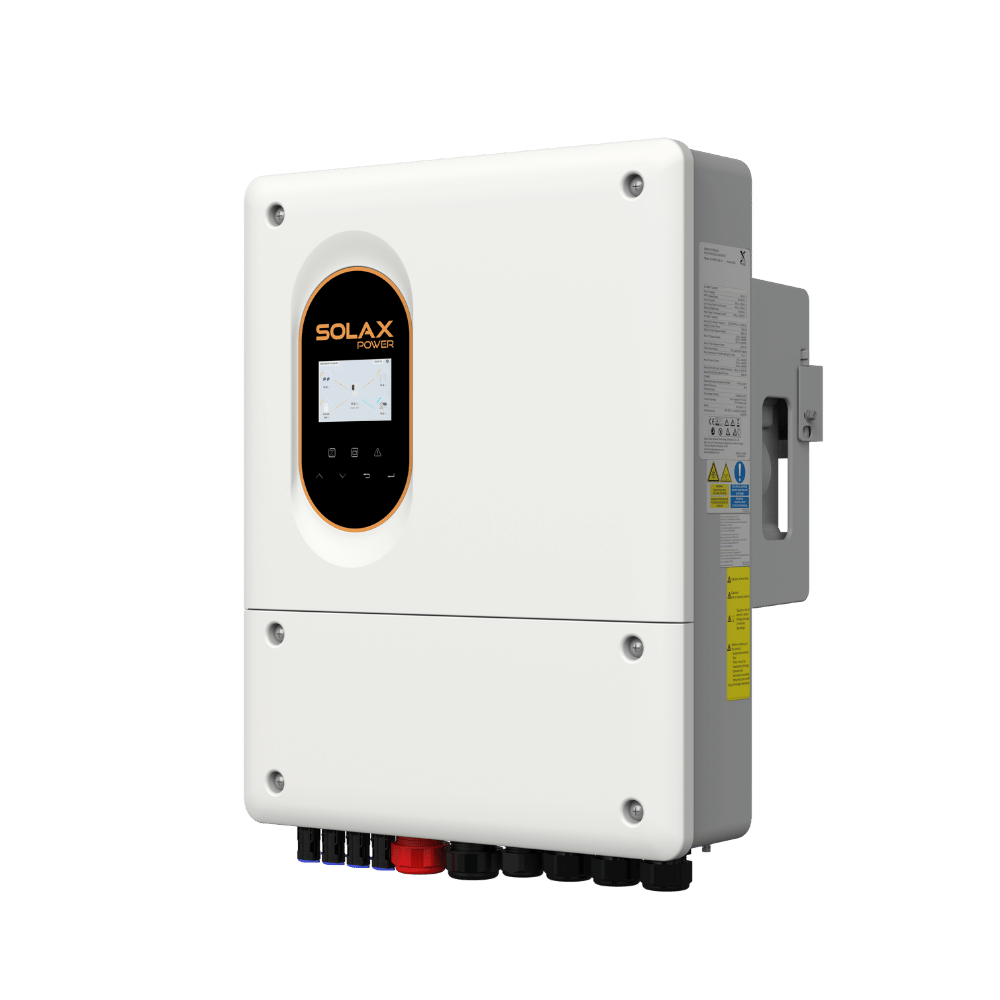

A hybrid solar inverter is often the bridge that makes PV+storage behave like a coordinated system rather than two separate assets. In a C&I setting, a hybrid platform can handle multiple operating modes: self-consumption, peak shaving, and demand management, and can also be configured for microgrid behavior if you need it.

The SolaX X3-AELIO hybrid solar inverter is positioned for this multi-mode reality, with VPP readiness and less than 10 ms switchover for on-grid/off-grid transitions. In its 49.9 kW variant, it lists up to 200% PV input, MPPT voltage range of 160 to 950 V, and multiple MPPT trackers, which can help when commercial rooftops have mixed orientations or partial shading zones.

Fleet and Workplace EV Charging Integration

EV charging can be a hidden driver of demand charges and peak load, especially when multiple vehicles plug in at shift change. When maintaining or commissioning the inverters and switchgear required for these high-power charging ecosystems, OSHA guidance under 29 CFR 1910.147 mandates strict lockout/tagout (LOTO) procedures to ensure de-energization and worker safety(OSHA).

The good news is that charging is highly controllable. If you coordinate a solar powered ev charger strategy with PV and storage, you can reduce the cost per mile and keep the utility meter calm. The key is to treat charging as a flexible load: you schedule it, cap it, and prioritize vehicles based on departure time and required energy.

A practical approach is layered control:

Use PV first when available.

Use battery to cover short gaps or prevent demand spikes.

Use grid energy primarily in off-peak windows.

This is where terms like ev solar charger and solar electric car charger become real system design choices, not marketing labels. In a workplace setting, the charger does not have to be fully solar-powered every minute. Instead, your system can ensure that net energy for charging is largely sourced from midday PV and low-cost periods, while the battery smooths the instantaneous power.

SolaX positions its ecosystem to integrate PV, ESS, and EV charging as one solution. While EV charger models vary by region, the Smart EV Charger G2 documentation in SolaX materials references smart connectivity and protocol support that matters when you want coordinated control rather than standalone charging.

How to Choose a System That Actually Lowers Bills

Load profile: size ESS to peaks, not just kWh

Sizing begins with power. Peak shaving is constrained by kW, not kWh. If your site spikes 150 kW above your target for 10 minutes, you need enough discharge power to cover that delta. Then you size energy to sustain the discharge for the peak duration plus buffer. This is why commercial energy storage systems are often specified in both kW and kWh and why your interval data matters more than monthly totals.

Tariff structure: target the best windows in a variable electricity tariff

Next, map your variable electricity tariff into actionable windows: expensive periods, demand measurement periods, and any ratchets. Your control plan should explicitly state what the battery does in each window: reserve, charge, discharge, or idle. If you cannot articulate that plan, you are not yet ready to size the system. A storage system that is oversized but misaligned with tariff windows can underperform a smaller system that is well-controlled.

Interconnection limits: plan export controls early

Export constraints can quietly determine ROI. If export is capped, you may prioritize self-consumption and curtailment reduction. If export is allowed but compensated poorly, you may still prefer on-site use. Either way, plan control modes that cap export, prevent reverse power flow when required, and avoid nuisance trips. Inverter settings, metering, and protection coordination should be part of the design scope.

Expansion plans: modular scaling roadmap

Finally, treat storage like a platform. If you expect additional EV chargers, a second production line, or expanded PV, plan for modular expansion. Scalable cabinets and parallel inverter capability can reduce future retrofit risk. The goal is to avoid rebuilding the control architecture each time you add capacity.

Comparison table: match scenario to control strategy

Application scenario | Primary bill driver | Recommended control approach | Key trade-offs |

High demand charges | Peak kW intervals | Peak shaving with demand cap | Needs SOC reserve discipline |

Strong TOU spread | kWh price windows | TOU arbitrage with controlled charging | Risk of demand spikes while charging |

Export capped | Curtailed PV | PV capture and self-consumption | Needs enough kWh to absorb midday surplus |

Outage-sensitive loads | Downtime cost | Backup reserve + fast islanding | Reduced energy available for arbitrage |

Growing EV charging | New coincident load | Managed charging + battery smoothing | Requires software integration and policy |

Conclusion

To slash commercial electricity bills, focus on what your tariff actually rewards and punishes: peaks, time windows, and reliability risk. Commercial battery storage paired with commercial solar power turns those bill drivers into controllable variables, especially when you treat the system as a monitored, scheduled asset rather than a set-and-forget installation. Start with 12 months of interval data, pick the highest-value use cases (peak shaving, TOU, self-consumption, resilience, EV charging), then size and control accordingly.

If you want a C&I cabinet example that is designed for scalable deployment with liquid thermal management and monitoring integration, explore here.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms