January 29, 2026

3 Critical Safety Layers Every Large-Scale Battery System Must Have

Share my #SolaXStory

For 2026, one theme keeps showing up across serious battery energy storage solutions: layered safety. Not one magic device, not one alarm, not one extinguisher. Instead, the most resilient commercial energy storage systems follow a sequence: detect early, isolate fast, and suppress decisively if things still escalate.

That same approach also supports smarter dispatch for solar power for business use cases, including demand response and vpp electricity programs, because reliability and control go hand in hand.

Below are the 3 critical safety layers every large-scale system must have, followed by SolaX Power examples built for C&I energy storage and commercial and industrial solar deployments.

The 3 Critical Safety Layers

1) Early Detection and Continuous Monitoring

If you want smart energy storage that performs safely under real load profiles, early detection is non-negotiable. The goal is simple: catch abnormal heat, gas, smoke, or electrical behavior before it becomes a cascading event.

In a commercial solar systems environment, early detection is also the difference between a planned service visit and an emergency shutdown that kills uptime.

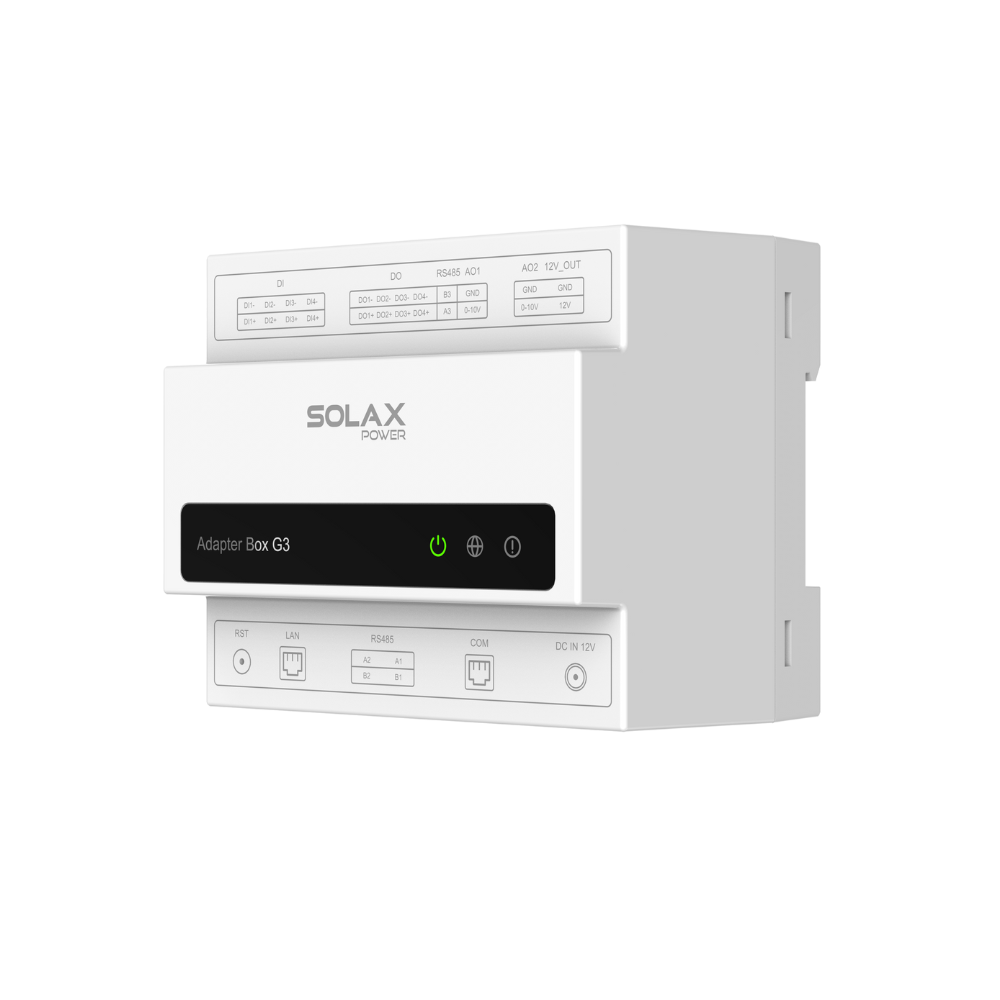

What does this look like in practice? It is a combination of sensing, analytics, and a monitoring platform that turns signals into decisions. A well-designed stack also helps operators run tighter schedules around a variable electricity tariff, because you can confidently dispatch the asset when you can see it clearly.

What to look for in sensor coverage?

You are not just looking for a single temperature probe. In large enclosures, bad things start locally, and the system only looks "fine" until it does not.

Focus on coverage that can feed both alarms and automated actions:

Temperature inputs across battery modules, racks, and thermal zones

Smoke and gas signals where accumulation is likely

Leakage detection aligned with cooling design and cable entry points

Door status and cabinet condition signals that flag access events and environmental exposure

Data paths that remain visible to operators, not trapped in a local controller

How does AI help spot problems sooner?

Analytics can compress the time between "slightly unusual" and "actionable warning." Instead of waiting for a hard threshold, systems can use health indicators to spot drift.

A practical view of AI support in commercial energy storage:

Cell health analytics and trend-based warnings that escalate before a thermal event

Faster alert routing to maintenance teams to shorten response time

Event correlation across sensors to reduce false positives (for example, ambient heat vs local hot spot)

In the ESS-TRENE Liquid Cooling product description, SolaX highlights AI-powered energy optimization via SolaXCloud, tying the monitoring layer to ongoing operational control rather than treating it as a standalone dashboard.

2) Electrical Isolation and Fault Containment

Detection tells you something is wrong. Isolation determines whether the problem stays small.

For battery storage utility scale projects and larger C&I installations, the key risk is propagation: a fault in one section can pull adjacent sections into stress through shared DC buses, shared protection boundaries, or common control logic. Isolation and containment are what keep a single fault from becoming a site-level outage.

This layer is also foundational for stable commercial solar inverters and hybrid solar inverter operation. When an inverter smart system can separate sections cleanly, you reduce collateral damage, simplify incident response, and restore partial service faster.

Where should circuit breaking happen?

Think in tiers. You want isolation boundaries that match how faults actually spread.

A practical checklist:

Rack-level isolation so local issues do not travel across parallel strings

PCS-level isolation to protect conversion equipment and downstream AC buses

Combiner-level or feeder-level disconnects aligned with the site electrical single-line

Protective coordination so the smallest relevant device trips first

SolaX specifically notes that its C&I energy storage inverter line includes protection features such as temperature detection for battery terminals and Type II SPD on both AC and DC sides, supporting a stronger electrical safety posture in mixed solar power storage systems.

What does enclosure protection rating add?

In the field, many faults start with environment: moisture, dust, salt air, or insects. IP ratings do not replace electrical design, but they reduce environmental triggers.

Look for IP ratings that match the sub-assembly:

IP66 inverter protection where equipment faces harsh site conditions

IP55 cabinet protection where C&I enclosures must manage dust and water jets

SolaX states that its C&I All-In-One ESS uses a 4-layer fire safety design, with IP66 for the inverter and IP55 for the cabinet, reinforcing the idea that physical protection is part of fault containment.

3) Fire Mitigation and Suppression Systems

If detection and isolation are the first two doors, suppression is the final door. The objective is to stop a thermal event from becoming a site-wide incident, limit impact to adjacent equipment, and meet safety expectations that are increasingly strict for utility solar power and C&I deployments.

This layer should be designed for speed and compartment behavior, not just "fire extinguishers exist." The more energy dense the system, the more important it is to slow spread and knock down re-ignition risks.

In 2025, safety compliance and testing methods continue to evolve, including updated approaches to evaluating thermal runaway fire propagation in BESS. UL Solutions highlights ongoing updates to UL 9540A:2025, reflecting how the industry is tightening expectations around thermal runaway behavior and protection design(e-Book: An Inside Look at the Updates to UL 9540A:2025).

SolaX Large-Scale Safety Examples

1) SolaX C&I All-In-One ESS (TRENE Series)

If your site needs commercial energy storage systems that can handle peak shaving, demand response, and backup power without stitching together five vendors, an all-in-one architecture can reduce both installation complexity and operational risk. The TRENE series is positioned for larger C&I use cases where integrated design matters: battery, PCS, thermal management, and distribution in one solution.

Key safety and operational points to consider:

Integrated architecture: battery, PCS, thermal management, and AC/DC distribution are combined in one unit, simplifying commissioning and reducing wiring failure points.

Capacity and power scaling: the C&I ESS overview highlights up to 261 kWh capacity and up to 125 kW power output in the all-in-one format, a common sizing block for commercial solar systems.

Fire safety design: the platform is described with a 4-layer fire safety design, supporting a suppression-ready approach rather than bolt-on protection.

Environmental protection: the same overview states IP66 for the inverter and IP55 for the cabinet, supporting commercial and industrial solar siting where dust and water exposure are routine.

Smart monitoring: the system integrates with SolaXCloud for 24/7 monitoring and is described as VPP-enabled, connecting safety monitoring to operational control.

2) SolaX ESS-TRENE Liquid Cooling (125kW/261kWh)

For many c&i energy storage projects, cooling is not just about efficiency. It is a safety tool. Liquid cooling is often chosen when you want tighter temperature uniformity across cells, especially under higher duty cycles such as frequent peak shaving or high cycling tied to a variable electricity tariff.

The ESS-TRENE Liquid Cooling product details provide several concrete safety and performance indicators:

Rated configuration: 125 kW / 261 kWh with LFP battery (314 Ah) and rated battery voltage listed as 832 V for this cabinet class.

Thermal control: SolaX states cell temperature differences under 3 C, a practical metric for reducing uneven aging and localized hot spots.

Electrical protection: the page calls out AC Type II SPD for electrical safety, supporting resilience against transient events common in commercial solar power sites.

Fire safety design: the product is described with a fire safety design approach and includes aerosol fire suppression for precise protection.

Environmental ratings: IP66 for the inverter and IP55 for the cabinet are highlighted, matching typical outdoor or semi-protected C&I installation realities.

Physical footprint reference: for the 261 kWh cabinet class, the page lists dimensions 1350 x 2355 x 1350 mm and weight 2810 kg, useful for planning layout, access, and separation.

3) SolaX C&I Energy Storage Inverters (X3-AELIO)

In many commercial solar systems, the inverter is the point where safety, control, and business value intersect. A hybrid solar inverter for C&I use must manage PV input, battery charging and discharging, and fast transitions between grid states without creating new fault paths.

SolaX positions X3-AELIO as a commercial hybrid solar inverter family (49.9 kW to 61 kW variants) with features that support both operational control and safety-minded behavior:

Fast transition behavior: switchover time is listed as under 10 ms, supporting continuity for sensitive loads and safer transitions when the grid is unstable.

PV oversizing support: product content highlights up to 200% PV input, which is relevant for commercial solar power systems that want higher PV-to-inverter ratios.

Parallel scaling: supports up to 10 parallel systems, covering roughly 49.9 kW to 600 kW, helping buyers scale inverter commercial capacity while keeping consistent controls.

VPP integration path: mentions IEEE 2030.5 and OpenADR support for VPP applications, connecting inverter storage assets to aggregated control and vpp electricity participation.

Key specs example: for X3-AELIO-49.9K, the parameters list MPPT voltage range 160 to 950 V, max recommended PV array power 100 kWp, and 5 MPPT with strings per MPPT listed as 5/2.

Form factor planning: dimensions are listed as 820 x 670 x 257 mm for the X3-AELIO-49.9K class, supporting enclosure and clearance planning.

4) SolaX C&I All-In-One ESS (TRENE-P125B261L-E variant)

When you are specifying commercial energy storage systems, the variant-level parameters matter because they affect protection settings, thermal planning, and site electrical coordination. One TRENE example listed on the liquid cooling page is TRENE-P125B261L-E.

Key technical details called out on the product page:

5) SolaX C&I All-In-One ESS (TRENE-P124B261L-E variant)

Not every project needs the same exact rated output, and in some markets, minor rating differences can align better with interconnection rules, tariff structures, or generator coordination. TRENE-P124B261L-E is another listed configuration in the same cabinet family.

What the published parameters highlight:

Rated AC power: 124.9 kW, essentially a 125 kW class unit.

Rated AC voltage options: 3 / N / PE, 220 / 380 V and 3 / N / PE, 230 / 400 V, supporting common three-phase commercial solar power integration.

Battery type and capacity: LFP / 314 Ah, 261 kWh capacity.

Physical and site constraints: dimensions 1350 x 2355 x 1350 mm and weight 2810 kg are listed, helping layout planning for commercial battery storage pads.

Operating environment: -30 to 55 C operating temperature range and 3000 m max altitude are listed, useful for harsh site evaluation.

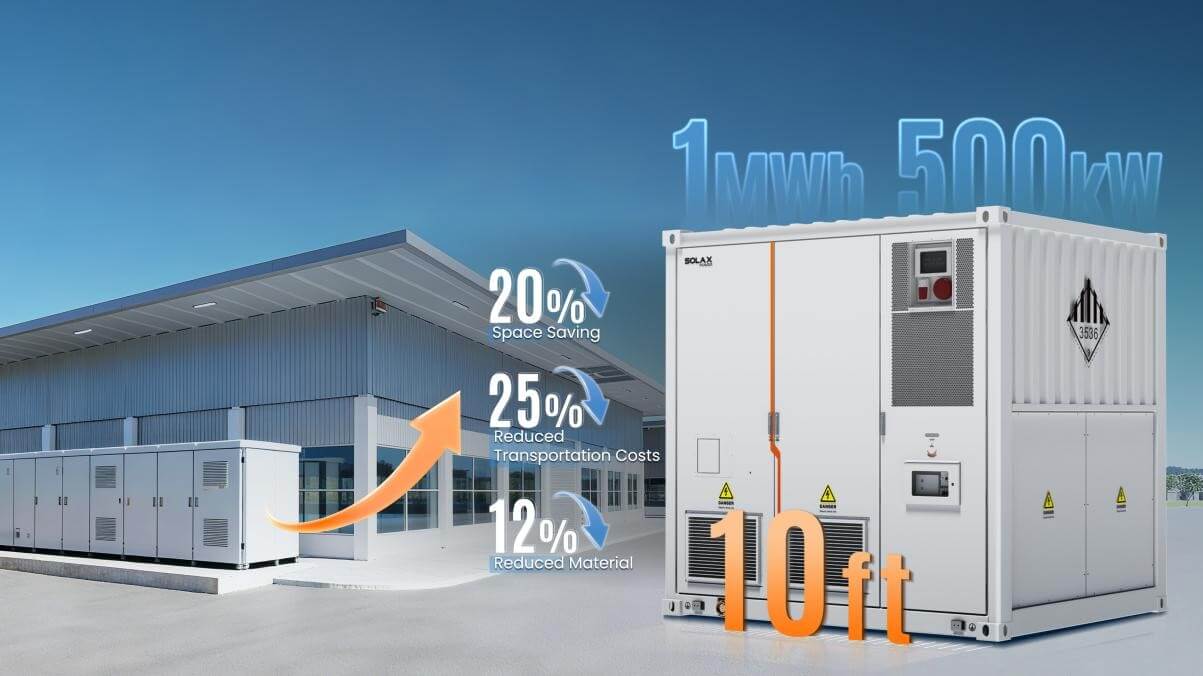

6) SolaX C&I ESS (TRENE-P249B1044L-4H variant)

As systems grow toward battery storage utility scale behavior, energy density and compartment planning become more important. The TRENE liquid cooling page lists a higher-capacity configuration: TRENE-P249B1044L-4H.

Key parameters shown on the page:

Rated AC power: 249 kW class.

Battery capacity: 1044 kWh with LFP / 314 Ah battery type listed.

Rated battery voltage: 832 V, keeping a consistent DC voltage class across multiple variants.

System footprint: dimensions listed as 2991 x 2896 x 2438 mm and weight listed as 13 t.

Operating environment: -30 to 55 C operating temperature range and max operation altitude 3000 m.

Ingress protection: IP55 is listed for ingress protection in the system parameter section.

7) SolaX C&I ESS (TRENE-P250B1044L-4H variant)

For commercial solar systems that need a 250 kW class block with a 1044 kWh cabinet, TRENE-P250B1044L-4H is another listed configuration on the ESS-TRENE Liquid Cooling page.

The variant parameters provide practical planning inputs:

Rated AC power: 250 kW.Battery capacity: 1044 kWh with LFP / 314 Ah.Rated battery voltage: 832 V.Physical parameters: dimensions listed as 2991 x 2896 x 2438 mm.Operating constraints: -30 to 55 C range with derating behavior above 45 C.

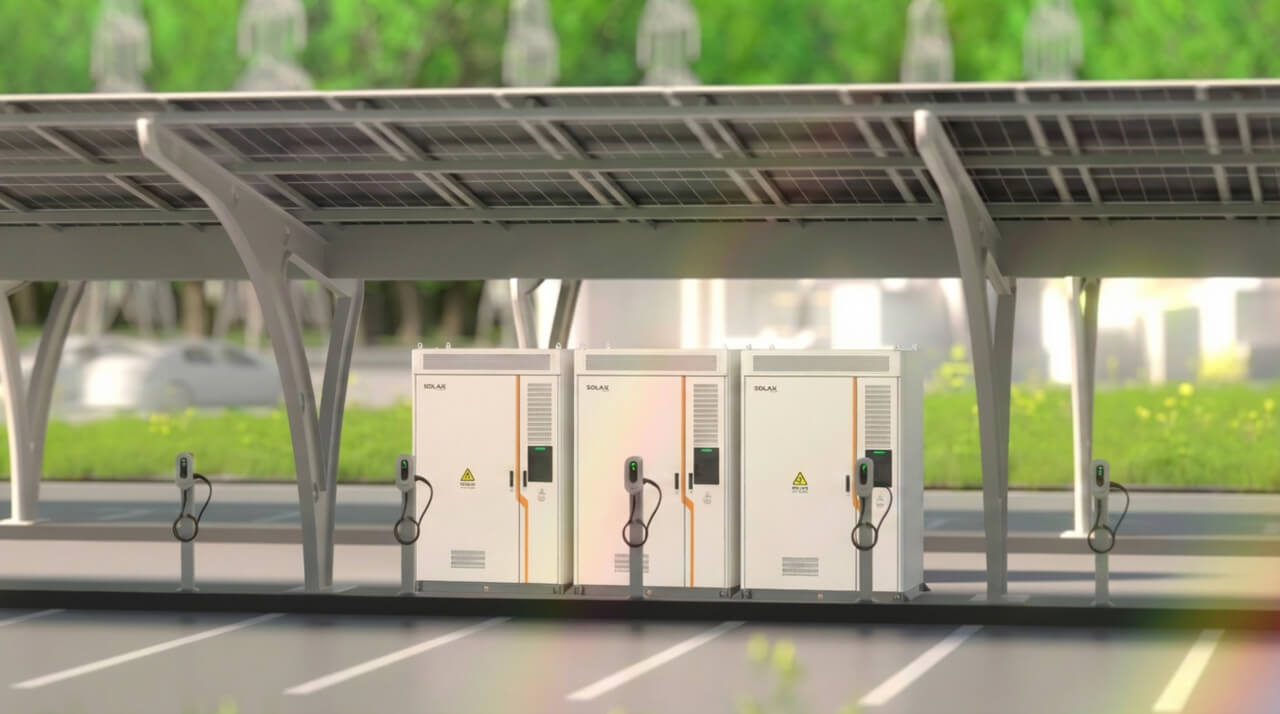

8) SolaX Smart EV Charger G2 (solar powered ev charger)

EV charging is increasingly part of commercial and industrial solar projects, especially for fleets. A solar powered ev charger can become a controllable load that soaks up midday PV, reduces export, and supports demand management. The important part is that it behaves predictably with the rest of the solar power storage systems stack.

SolaX Smart EV Charger G2 is positioned as a next-generation charger with solar compatibility and remote control via SolaXCloud:

Power classes: listed as 4.6 kW, 7.2 kW, 11 kW, and 22 kW.

Connectivity: listed 3 modes connectivity (WiFi / 4G / Ethernet), supporting remote control and monitoring.

Solar compatibility: described as solar compatible and designed to optimize power usage.

Load management: includes dynamic load balancing and smart dynamic load balance control, reducing the risk of site overloading.

Safety protections: current leakage protection is listed as 30 mA AC and 6 mA DC.

Green charging behavior: the product advantage section states support for 100% green energy charging and maximizing surplus energy utilization in a zero-export system.

9) SolaX Smart EV Charger G2 (ev solar charger site control angle)

Some buyers evaluate chargers only on power rating. In C&I, the bigger question is coordination: can the solar electric car charger behave as part of the site energy system rather than a random load? That matters for commercial solar power projects where export limits, peak demand, and scheduling rules create operational constraints.

From the published product content, G2 includes several features that support system-level coordination:

Remote scheduling and monitoring via the SolaXCloud App, which helps align charging with PV production and tariff windows.

Automatic switching between single- and three-phase power, supporting different site electrical conditions.

Support for multiple communication protocols (listed under flexible adaptability), which can matter when integrating chargers into broader site controls.

RFID management for controlled access, relevant for fleet and workplace charging environments.

10) SolaX X3 FORTH PLUS (string inverter option for commercial solar systems)

Not every commercial system uses a hybrid solar inverter at the PV level. Many commercial solar systems use string inverter architectures on the PV side, then integrate storage through separate power conversion or hybrid subsystems. In those designs, the string inverter still affects safety indirectly by influencing DC behavior, site protection coordination, and operational stability.

The X3 FORTH PLUS product page content includes a clear reference point on system planning:

The page positions X3 FORTH PLUS as a three phase string inverter product line.

It links into the same ecosystem of commercial solar inverters that can be part of a broader commercial energy storage systems deployment.

In the broader SolaX portfolio, string inverter families are listed under Commercial and Industrial String Inverters, supporting commercial solar power projects where PV and storage may be designed as separate blocks.

Comparison Table

Quick safety-focused checklist (SolaX options)

Solution | Safety layers | IP rating | Monitoring | Surge protection | Cooling | Best-fit scenario |

C&I All-In-One ESS (TRENE) | Detection + isolation + suppression-ready design | IP66 inverter, IP55 cabinet | SolaXCloud 24/7 monitoring, VPP-enabled | Integrated protective design approach | Liquid cooling mentioned in platform overview | Commercial solar power sites needing integrated storage for peak shaving, demand response, and backup |

ESS-TRENE Liquid Cooling 125kW/261kWh | Detection + isolation + aerosol suppression emphasis | IP66 inverter, IP55 cabinet (also notes IP67 battery) | AI-powered optimization via SolaXCloud, VPP ready | AC Type II SPD | Liquid cooling; cell delta under 3 C | High-cycling C&I sites needing tighter thermal control and stable operation under a variable electricity tariff |

C&I Energy Storage Inverters (X3-AELIO) | Detection signals + fast transition control (system role) | Not specified on product page excerpt; verify per variant | Remote monitoring and OTA mentioned | Not specified on X3-AELIO page excerpt; see C&I inverter family notes | Not applicable | Hybrid solar inverter blocks for commercial solar systems, including microgrid and VPP integration |

Conclusion

The safest large-scale battery system is not defined by a single feature. It is defined by how the layers work together: detect early, isolate quickly, and suppress decisively if escalation happens. That layered approach reduces incident risk and also improves uptime, which directly supports commercial solar power ROI under a variable electricity tariff.

If you are building or upgrading commercial energy storage systems, use the three-layer lens first, then map products to your site reality: enclosure environment, cycling intensity, interconnection rules, and operating objectives like peak shaving, backup, and vpp electricity participation.

To explore SolaX commercial energy storage systems for C&I applications, start with the TRENE platform and the X3-AELIO hybrid solar inverter family.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms