January 29, 2026

Liquid Cooling vs. Air Cooling for MWh Energy Storage: Key Differences Explained

Share my #SolaXStory

For C&I energy managers, EPCs, and operators building battery energy storage solutions in the 1 MWh-plus range, the real question is not "which cooling is better?" It is "which cooling is better for my duty cycle, climate, and service model - while still supporting VPP electricity programs and modern controls?"

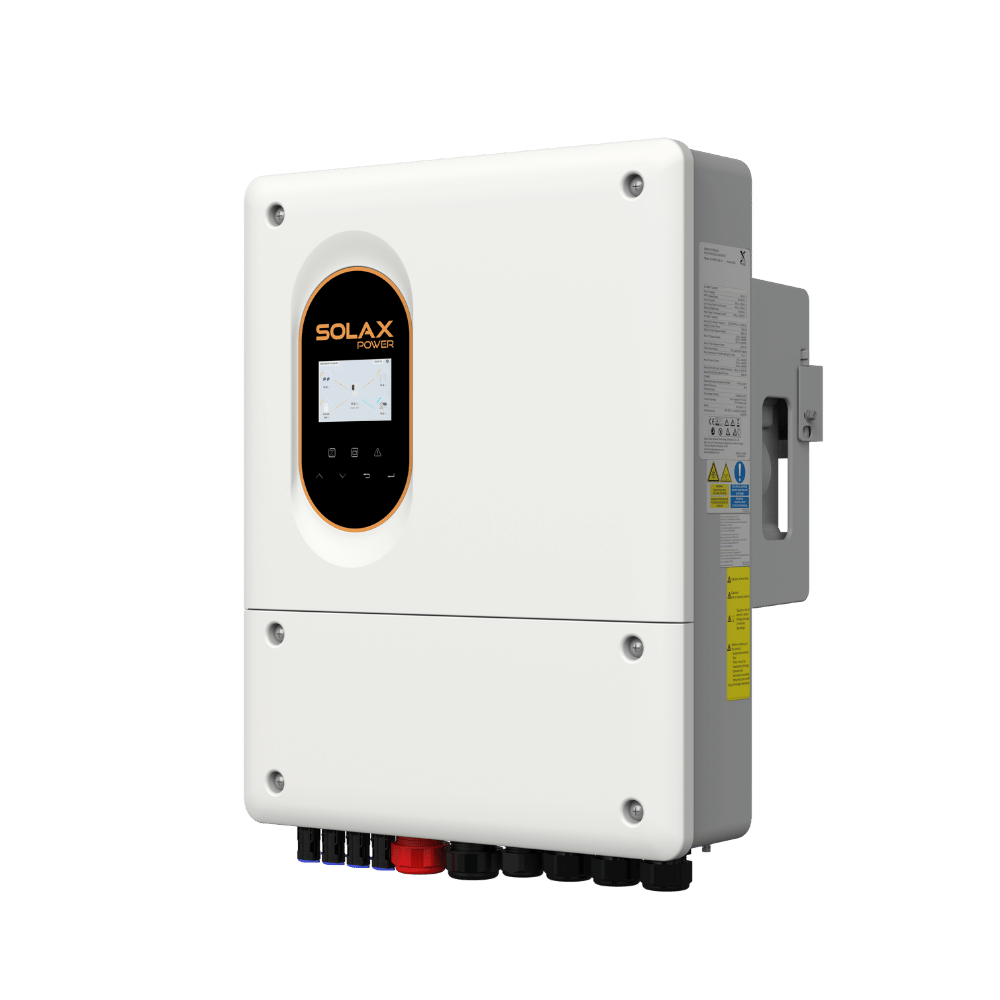

SolaX Power approaches that question with two C&I cabinets in the same family: ESS-TRENE Liquid Cooling (261 kWh / 125 kW class) and ESS-TRENE Air Cooling (215 kWh / 100 kW class), both designed to scale to megawatt-hours and integrate smart monitoring via SolaXCloud.

What Changes Most: Liquid vs. Air Cooling?

Both options can deliver strong results for commercial solar power paired with a solar energy storage system. However, cooling changes how heat is removed, which changes thermal spread, component stress, and maintenance routines.

At a high level:

Liquid cooling moves heat through a coolant loop, targeting tighter temperature control inside the battery and power electronics.

Air cooling moves heat by managing airflow through the enclosure, usually aiming for simpler service and fewer fluid-loop components.

So what fails first in your environment: thermal uniformity, peak-load performance, or site maintenance capacity?

Thermal Uniformity (Why delta-T matters)

If you are cycling daily for commercial energy storage systems dispatch, temperature spread (delta-T) becomes a practical KPI, not a lab metric. Large temperature differences inside a pack can increase uneven aging, which can complicate long-term performance planning.

SolaX highlights that its TRENE liquid cooling design maintains cell temperature differences under 3 C, which is a strong signal for operators who prioritize consistent performance under repeated cycling.

Ask yourself:

Are you trying to protect cycle life in a high-utilization solar power storage systems program?

Do you need predictable performance for VPP electricity obligations?

Performance Under Peak Load

Peak-load performance is where cooling shows up as derating. If your site sees long stretches above 45 C ambient, you should model how much time you will operate in derating zones - because that is when demand shaving and TOU arbitrage can lose ROI.

Both TRENE variants publish operating ranges and derating notes. For example, TRENE liquid cabinet models list an operating temperature range of -30 to 55 C with derating above 45 C, and the air-cooled cabinet lists -30 to 50 C with derating above 45 C.

A quick operator question:

Do you need extra headroom during the hottest month when commercial solar systems output is high and tariffs are sharp?

O&M Complexity and Access

Cooling selection is also a service strategy decision.

Air cooling typically implies routine checks around airflow paths, fans, and keeping intake/exhaust clear.

Liquid cooling adds a cooling loop (pumps, coolant condition checks, and leak inspection) but can improve control of internal temperatures in high-duty scenarios.

If you are a multi-site operator, the question becomes:

Which maintenance profile can your team execute fastest and most consistently across locations?

SolaX Examples: Which TRENE Fits Your Site?

SolaX Power positions TRENE for common C&I deployments - factories, malls, and other large-load sites - and frames it within a broader portfolio that spans commercial solar power, storage, and PV + ESS + EV charging integration.

When Liquid Cooling Is the Better Call

Liquid cooling usually makes the most sense when you have one or more of the following:

Hot climates or harsh enclosures where stable thermal control matters

Higher utilization (daily cycling, peak shaving plus arbitrage)

Power-forward operation where you want less thermal stress at high output

In the TRENE line, liquid cooling also aligns with higher per-cabinet energy (261 kWh class) and model options that scale toward MWh blocks.

When Air Cooling Makes More Sense

Air cooling can be the better fit when you prioritize:

Straightforward service routines

Space-conscious installations with modular deployment

Solid controls and VPP-ready communications without the additional liquid-loop service profile

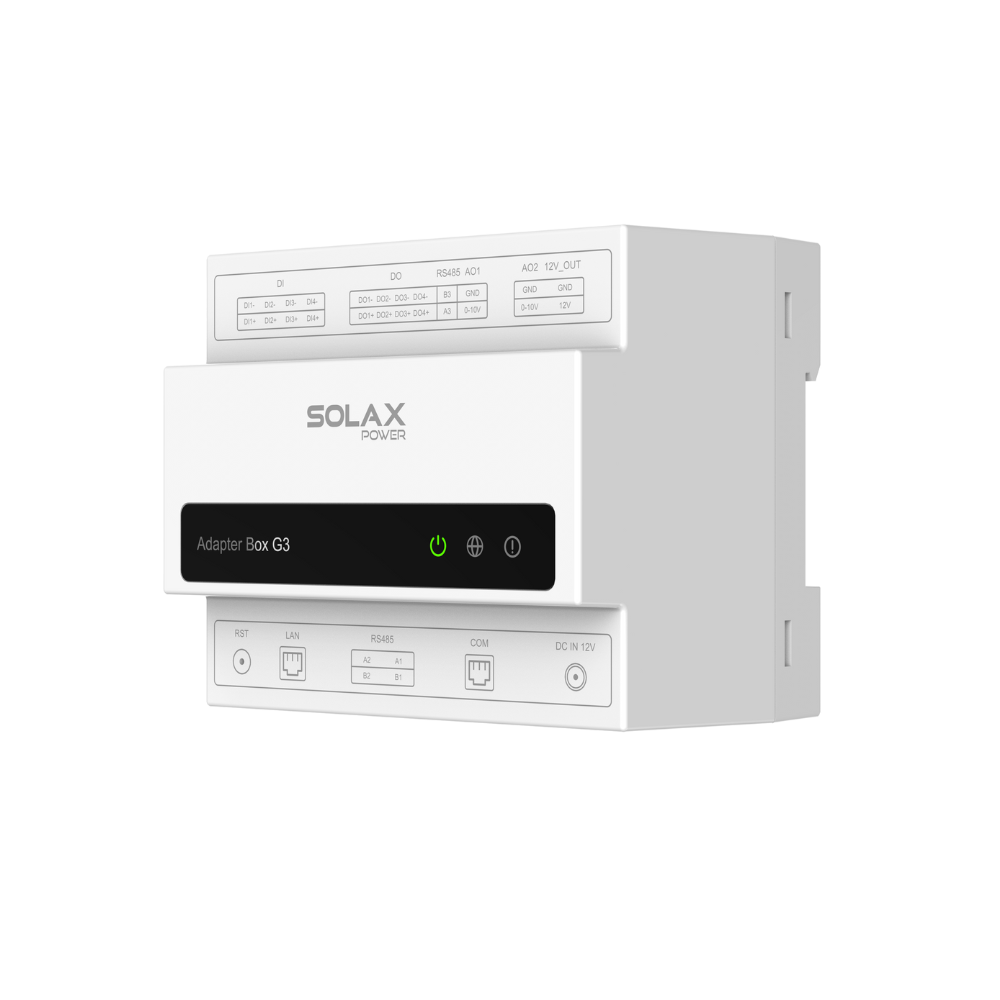

SolaX positions its air-cooled TRENE cabinet as compact and space-optimized while still supporting smart schedule features and VPP-ready integration via SolaXCloud (IEEE 2030.5, OpenADR).

The Picks: SolaX Cooling Options for MWh Builds

Below are 7 practical "picks" (configuration options) that map to common C&I build patterns. While several entries are model variants, treat them as dispatch-focused building blocks for battery energy storage solutions design: matching kW, duration, and operational constraints.

1. ESS-TRENE Liquid Cooling

Best for: high-duty commercial energy storage at factories, malls, and other large-load sites where summer peaks and frequent cycling amplify thermal stress

Cooling approach: liquid cooling designed for tighter thermal control

Capacity class: 261 kWh stand-alone capacity and 125 kW output class (with peak output noted on the product page)

Battery chemistry: LFP, with 314 Ah cells referenced for this platform

Safety positioning: four-level fire protection is called out for the TRENE platform

Controls: positioned as smart energy storage with monitoring and energy management via SolaXCloud, supporting VPP readiness (IEEE 2030.5, OpenADR)

2. TRENE-P125B261L-E

Best for: sites that need a clear 125 kW AC block size for modular scaling in commercial energy storage systems

Rated AC power: 125 kW

Battery: LFP / 314 Ah

Battery capacity: 261 kWh

Rated battery voltage: 832 V

Operating temperature range: -30 to 55 C (derating above 45 C)

Ingress protection: IP55 (cabinet)

3. TRENE-P124B261L-E

Best for: interconnection or design scenarios where you need to match an AC rating just under 125 kW

Rated AC power: 124.9 kW

Battery: LFP / 314 Ah

Battery capacity: 261 kWh

Rated battery voltage: 832 V

Operating temperature range: -30 to 55 C (derating above 45 C)

Physical footprint: cabinet dimensions are published on the product parameters table

4. TRENE-P249B1044L-4H

Best for: larger block builds targeting a 4-hour energy shifting profile for commercial solar power plus storage

Rated AC power: 249 kW

Battery capacity: 1044 kWh

Battery: LFP / 314 Ah, 832 V rated battery voltage

Operating temperature range: -30 to 55 C (derating above 45 C)

Use-case question: Are you building around TOU arbitrage windows that favor longer discharge duration?

5. TRENE-P250B1044L-4H

Best for: standardized 250 kW class blocks in a scalable solar energy storage system design

Rated AC power: 250 kW

Battery capacity: 1044 kWh

Battery: LFP / 314 Ah, with 832 V rated battery voltage

Enclosure: IP55 cabinet rating is listed on the product parameters table

Deployment question: Do you need repeatable 250 kW steps to simplify protection settings and spares strategy?

6. TRENE-P260B1044L-4H

Best for: power-forward 4-hour builds where demand charge management needs extra kW ceiling

Rated AC power: 260 kW

Battery capacity: 1044 kWh

Battery: LFP / 314 Ah, 832 V rated battery voltage

Operating envelope: -30 to 55 C (derating above 45 C)

Operator question: Are you optimizing for peak demand shaving rather than just energy shifting?

7. TRENE-P319B1044L-3H

Best for: higher power density applications where a 3-hour duration is the target

Rated AC power: 319.6 kWBattery capacity: 1044 kWh

Duration logic: 3-hour class can fit dispatch that prioritizes power delivery over extended runtime

Thermal context: if you are pushing sustained high kW, cooling and derating behavior matter more than nameplate

How Do You Choose Cooling for MWh ESS?

Cooling is not a standalone decision; it is coupled to dispatch, climate, and service execution. Use this as a field checklist for selecting commercial energy storage systems that integrate cleanly into commercial and industrial solar projects and, increasingly, EV charging.

One trend that matters: grid operators and utilities continue scaling battery storage, which pushes more sites toward controllable, dispatchable assets rather than passive backup systems. National Renewable Energy Laboratory analyses also emphasize the importance of performance assumptions (efficiency, lifetime, and O&M) in long-term storage planning. (National Renewable Energy Laboratory)

Comparison Table

Option | Cooling | kW | kWh | Battery cell rating | Operating temp range | Ingress protection | VPP-ready notes |

ESS-TRENE Liquid Cooling (platform) | Liquid | 125 kW class | 261 kWh class | LFP / 314 Ah | -30 to 55 C (derating >45 C) | IP55 | SolaXCloud, IEEE 2030.5, OpenADR |

TRENE-P125B261L-E | Liquid | 125 kW class | 261 kWh class | LFP / 314 Ah | -30 to 55 C (derating >45 C) | IP55 | SolaXCloud, VPP-ready positioning |

TRENE-P249B1044L-4H | Liquid | 249 kW class | 1044 kWh class | LFP / 314 Ah | -30 to 55 C (derating >45 C) | IP55 | SolaXCloud, VPP-ready positioning |

Conclusion

For commercial energy storage buyers building MWh-class systems, the liquid vs air cooling decision is really about matching thermal control to operating reality.

If you are integrating commercial solar power, commercial battery storage, and future EV charging (from an ev solar charger to a solar powered EV charger fleet strategy), start with dispatch modeling under your variable electricity tariff, then select the TRENE block that best fits your climate and service capacity.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms