January 28, 2026

Grid Security Solved: Essential Steps for Securing Backup Power for Your Commercial Site

Share my #SolaXStory

Keeping a commercial site running through grid instability is no longer just a “nice-to-have”—it's a resilience requirement. In 2026, more C&I operators are pairing on-site generation with energy storage to protect operations, reduce demand charges, and keep critical loads online during outages.

This how-to guide walks you through practical, step-by-step actions to plan, configure, and validate a commercial backup-power system built around SolaX Power's liquid-cooled ESS TRENE system.

Secure Commercial Backup Power Step by Step

1: Define critical loads and autonomy targets

Before choosing any equipment settings, document what "backup power" must actually do at your site. Start by listing critical loads and separate them from non-critical loads. Then translate that list into two numbers: kW (instantaneous power) and kWh (energy over time).

Next, choose an autonomy target aligned to your risk profile. Many sites aim for 1–4 hours of full critical-load support, then a longer "degraded mode" where only the most essential circuits remain powered.Confirm whether you need true islanded operation (microgrid behavior) or simply peak shaving plus short ride-through.

Finally, capture operational constraints: acceptable voltage/frequency limits for sensitive equipment, maximum transfer time, and whether any loads require soft-start or sequential restart.

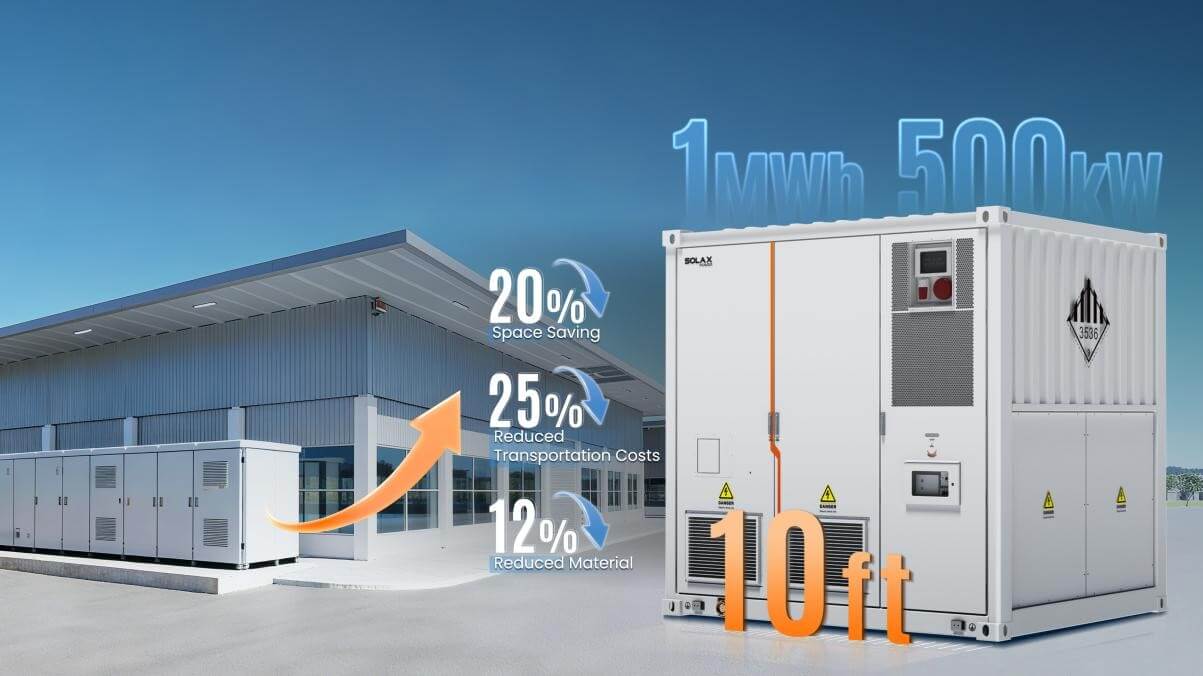

2: Select a TRENE liquid ESS configuration and site layout

Once your load and autonomy targets are defined, map them to a containerized storage approach and physical layout. Then decide where the ESS should sit relative to the transformer, switchgear, and any PV or generator interconnect.

SolaX Power's ESS TRENE is positioned as a liquid-cooled, C&I-focused energy storage solution intended for stable thermal management and consistent operation.

To make the configuration selection practical, align these factors:

Peak critical kW vs. inverter/PCS capability (avoid operating continuously at the ceiling).

Required kWh vs. usable capacity (plan headroom for aging, temperature, and reserve SOC).

Duty cycle (daily peak shaving + backup events) vs. expected thermal load.

Monitoring and controls integration needs (SCADA/BMS, alarms, remote O&M).

3: Configure operating modes for resilience first

After the system is physically planned, define how it will behave day-to-day and during a grid event. A common mistake is to optimize purely for economics (maximum peak shaving) and accidentally leave insufficient energy for outages.Use a layered strategy:

Normal mode (grid-connected): peak shaving, TOU arbitrage, PV self-consumption, demand charge management.Standby reserve: maintain a minimum SOC (often 20–40% depending on risk tolerance and autonomy requirements).Backup mode (grid event): isolate critical loads (via ATS/microgrid controller or site switchgear logic), enforce discharge limits, and manage restart sequencing.

4: Commission monitoring, alarms, and remote control workflows

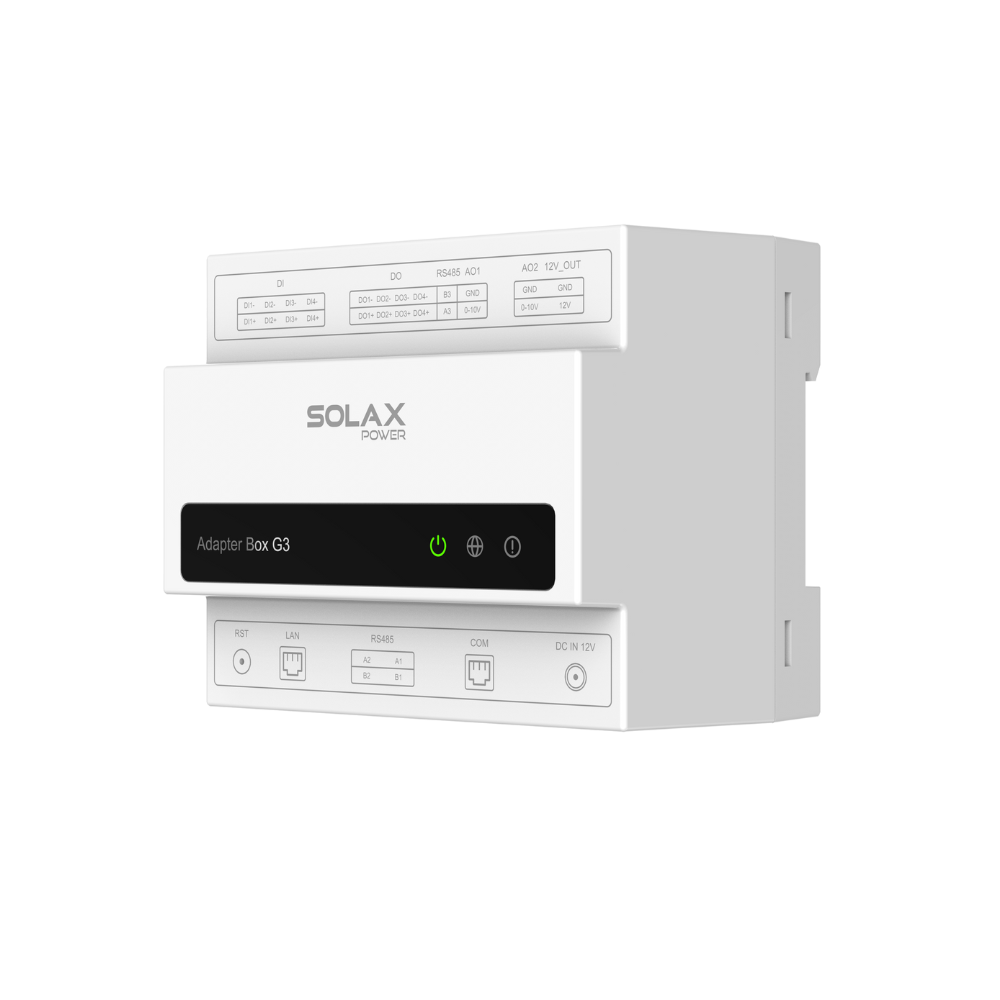

A resilient backup-power plan fails if you can't see what's happening in real time. During commissioning, validate that monitoring and alarms work end-to-end: from sensors and the BMS/EMS layer, through your site network, to the dashboard and alerting destination used by operators.

Build a monitoring checklist that includes:

SOC, charge/discharge power, and energy throughput trends.

Cooling system health indicators (coolant temperature, pump status, thermal alarms).

Electrical protections (over/under voltage, frequency excursions, insulation monitoring if present).

Event logs for grid loss, transfer actions, and fault history.

Communications status (heartbeat, latency, data gaps) to ensure you're not “blind” during an incident.

SolaX Power's ecosystem includes cloud monitoring and energy management capabilities (SolaXCloud) that are designed for real-time visibility and optimization across assets. For a commercial site, define roles and responsibilities: who receives alarms after hours, how fast escalation occurs, and what actions are allowed remotely versus on-site only.

5: Validate backup performance with a controlled grid-loss test

A plan is only as strong as the last successful test. After commissioning, perform a controlled backup-power validation in coordination with your electrical contractor and site safety lead. The test should simulate a grid loss and verify that critical loads remain stable, transfer logic works, and the ESS returns to normal operation safely afterward.Use a staged approach:

Pre-test readiness: confirm SOC above your test threshold, no active alarms, and that emergency stop access is clear.

Islanding/transfer test: simulate grid loss, confirm critical-load bus remains within acceptable voltage/frequency limits, and document transfer time.

Sustained run: hold operation for a defined duration (e.g., 15–60 minutes) to check thermal and power stability.

Restart sequencing: bring back loads in planned order to prevent inrush spikes and nuisance trips.

Return-to-grid: confirm synchronization/transfer back logic and verify the system resumes normal reserve management.

For general electrical safety expectations in industrial environments, OSHA emphasizes protecting employees from electrical hazards through safe work practices and appropriate controls (osha.gov). Use that guidance to structure who can operate switchgear, what PPE is required, and how lockout/tagout is applied during test events.

TRENE liquid Backup Power in Different Scenarios

High-heat sites (hot climates or rooftop-adjacent yards): Increase your reserve SOC slightly and schedule heavier cycling during cooler hours when possible. Validate that coolant and container thermal alarms remain well below thresholds during peak ambient. In these environments, TRENE liquid cooling is often chosen to reduce temperature swings that can trigger derating.

Sites with frequent short outages (seconds to minutes): Prioritize fast detection and transfer logic, and configure the ESS to handle repeated shallow discharge events without draining reserve. Test multiple “blips” back-to-back so you can verify the system doesn't latch into a fault state after the third or fourth event.

PV-heavy sites (midday surplus, evening peaks): Use storage to capture midday overproduction while maintaining a backup reserve floor. If islanding with PV is required, confirm the control scheme supports stable microgrid operation and does not trip on voltage/frequency excursions when clouds pass.

Process loads with large inrush (motors, compressors): Implement staged restart and consider limiting instantaneous discharge power to reduce stress on electrical components. Validate that the ESS can support motor starts without voltage sag that could trip drives or PLC power supplies.

Troubleshooting

Problem | Cause | Fix |

Backup runtime is shorter than expected | Reserve SOC set too low, critical loads higher than the load list, or power limits causing early shutdown | Re-measure critical loads at the main and critical-load panels, raise minimum SOC reserve, and repeat the grid-loss test with a sustained run and logged kW/kWh. |

System derates during sustained discharge | High ambient temperature, cooling loop issue, or conservative thermal limits | Check coolant temperature trends, verify pump/fan operation, clean/clear container ventilation paths, and adjust discharge power limits to keep temperatures stable. |

Nuisance trips during transfer to backup | Inrush currents, poor restart sequencing, or protection settings not aligned with load behavior | Implement staged restart (largest motors last), add soft-start/VFD settings where possible, and coordinate protection settings with the electrical engineer. |

Monitoring shows data gaps during events | Network instability, firewall rules, or insufficient local buffering | Validate wired connectivity, whitelist required ports/addresses, and ensure local event logging continues even if cloud connectivity drops. |

SOC does not recover after an outage | Control mode still in backup state, PV/generator coordination issue, or charge limits too strict | Confirm return-to-grid state machine, verify charging permissions and limits, and review whether reserve logic prevents charging above the threshold. |

Conclusion

Securing commercial backup power is mainly about discipline: define critical loads, choose a realistic autonomy target, configure modes that protect reserve energy, and validate performance with controlled testing. With a liquid-cooled approach like ESS TRENE using TRENE liquid thermal management, you can build a more predictable resilience strategy for high-duty or high-heat environments—provided monitoring, safety workflows, and commissioning checks are done thoroughly.

If you're planning a containerized backup-power deployment, review the C&I solution details and align them to your site's operating modes and test plan.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms