December 31, 2025

The 6 Best Strategies for Peak Demand Shaving in Factory Operations

Share my #SolaXStory

Introduction

The global electricity system is navigating a period of intense pressure driven by pervasive electrification, robust industrial load growth, and the escalating demands of expanding data center infrastructure. The scale of energy storage is expanding at a record-breaking pace. As we enter 2026, the global utility-scale energy storage market has reached a critical tipping point. The urgency for utility-scale solutions is underscored by recent data from BloombergNEF, which forecasts a record-breaking year in 2025 with 94 GW of new energy storage capacity—a 35% surge from the previous year. As the market accelerates toward projected annual additions of 220 GW by 2035, representing a 14.7% compound annual growth rate, the industry is shifting its focus toward high-density Lithium Iron Phosphate (LFP) systems(BloombergNEF: Global Energy Storage Boom).

Success in the utility-scale ESS sector is not dependent on the performance of a single component but rather on the disciplined integration of deployment and operational levers into a repeatable, high-reliability playbook. This comprehensive guide details six practical strategies essential for achieving accelerated grid interconnection, optimizing energy utilization across various market services, and maintaining exceptional reliability in multi-megawatt deployments. It highlights specifically how advanced, containerized solutions like the SolaX ORI Liquid Cooling ESS System address these challenges, serving as a core component for Utility-Scale Plant Solutions.

The Landscape: Utility Deployment Challenges

While infrastructure costs remain a challenge, the core technology is more accessible than ever. Wood Mackenzie reports that average BESS prices have plummeted by 10% to 40% in just the last year(Wood Mackenzie: BESS Opportunity).

Utility-scale BESS projects, unlike smaller installations, demand meticulous adherence to strict regulatory and technical standards, including stringent interconnection requirements, complex SCADA integration, and coordination with Independent System Operators (ISOs). The focus shifts entirely from local facility peak management to maximizing power and energy delivery for grid support and arbitrage.

Utility-Scale Challenge | Deployment Strategy Focus | ORI Feature Solution |

Long On-Site Work | Minimize field integration time | Factory pre-assembly & pre-commissioning |

Thermal Degradation | Maintain precise thermal uniformity | Liquid Cooling with ≤3°C uniformity |

Grid Compliance | Ensure coordinated electrical protection | Collaborative Protection with 4-layer fuse protection |

Revenue Optimization | Maximize energy output and efficiency | Intelligent clusters, High-efficiency 99.04% PCS |

The 6 Essential Strategies for Utility ESS Success

1) Real-time Monitoring and AI-Driven Anomaly Detection

System visibility is the bedrock of utility ESS success, guaranteeing both maximized uptime and intelligent safety. For large fleets, the failure to quickly diagnose an operational issue—what turned on, when, and why—can lead to treating symptoms rather than addressing the core fault. Therefore, Comprehensive Monitoring is mandatory, relying on real-time, full-spectrum data collection.

A crucial utility best practice is the implementation of AI-driven anomaly detection. This sophisticated approach surpasses simple fixed thresholds, detecting subtle deviations in temperature or electrical performance that may signal a precursor to a fault before it escalates. The ultimate operational goal is to use this detection to trigger an automated runbook, initiating controlled corrective actions—such as system isolation or a coordinated shutdown—to protect the grid asset immediately. This approach is essential for maintaining reliability and intelligent safety across vast, interconnected fleets.

Best for: Maintaining high reliability and intelligent safety across large utility fleets.

Operational win: Automated fault isolation minimizes system impact and facilitates faster root-cause analysis after any event.

Common pitfall: Collecting vast amounts of data without ensuring it is seamlessly tied to automated, immediate corrective actions (“dashboard tourism”).

2) Strategic Energy Dispatch for Arbitrage and Grid Services

The most fundamental commercial lever for a utility asset is strategic dispatch—the precise scheduling of energy injection (discharge) and absorption (charge) to maximize financial returns. This strategy involves two primary objectives: maximizing revenue based on fluctuating market price signals (energy arbitrage), and fulfilling technical requirements for specific grid service contracts (such as frequency regulation or capacity reserves).

Optimal dispatch is achieved by accurately forecasting and identifying market windows where energy is inexpensive for charging, followed by discharging during periods of peak market value or critical grid necessity. SolaX solutions leverage Smart Energy Management features, including SolaXCloud and potential VPP (Virtual Power Plant) integration, to execute this strategic dispatch,. The system's Intelligent clusters and Smart controls are engineered to maximize output and efficiency based on these complex economic levers, ensuring maximum energy utilization throughout the system's life.

Best for: Systems focused on maximizing revenue through dynamic market participation and capitalizing on repeatable peak value windows.

Operational win: Optimizes the asset's utilization cycle, enhancing returns and reducing the risk of accidental dispatch failures.

Common pitfall: Dispatch scheduling that relies exclusively on fixed historical patterns or simple time-of-day tariffs, failing to dynamically adapt to real-time market volatility.

3) Coordinated Protection and System Integrity

In utility BESS, catastrophic performance issues are often triggered by transitions—specifically, uncoordinated ramp-ups, abrupt disconnections, or synchronized starts after a stoppage. Ensuring system coordination is paramount, with a singular focus on preventing dangerous electrical spikes and guaranteeing rapid, controlled fault isolation.

This strategy necessitates designing for Collaborative Protection, which aims to convert an abrupt fault into a controlled ramp-down or isolation sequence executed over milliseconds. The SolaX ORI system addresses this through multi-layered electrical safety, including 4-layer fuse protection and dual-layer insulation monitoring. Furthermore, the system includes a Coordinated shutdown mechanism specifically designed to reduce the spread of failure and minimize component damage during abnormal events.

Best for: Enhancing system reliability and protecting equipment during fault conditions, large-scale transitions, and grid disturbances.

Tools: Advanced control logic, high-speed circuit protection, integrated isolation components, and robust insulation monitoring.

Operational win: Prevents avoidable electrical spikes and cascading failures without compromising critical grid stability.

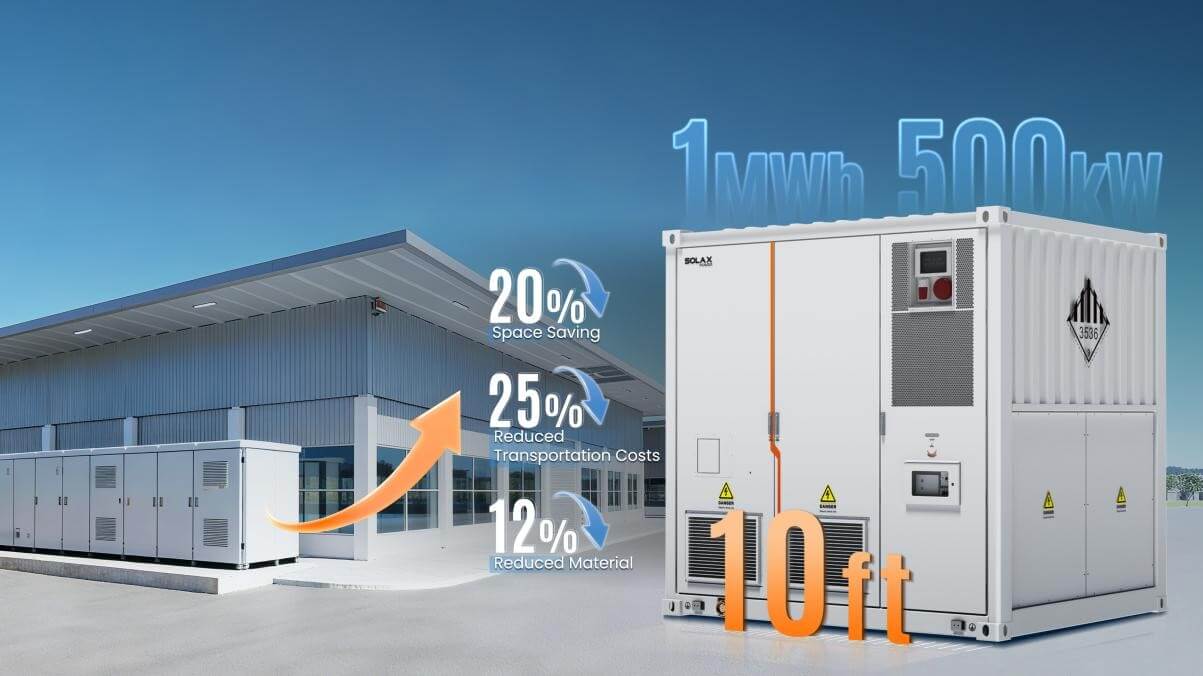

4) Leveraging the ORI Containerized ESS for Peak Performance and Thermal Stability

Grid stability is becoming a critical bottleneck. Wood Mackenzie identifies a massive 1,400 GW gap in grid-forming capacity needed over the next decade to stabilize networks as renewable penetration grows(Wood Mackenzie: US$ 1.2 trillion in battery storage investments needed).

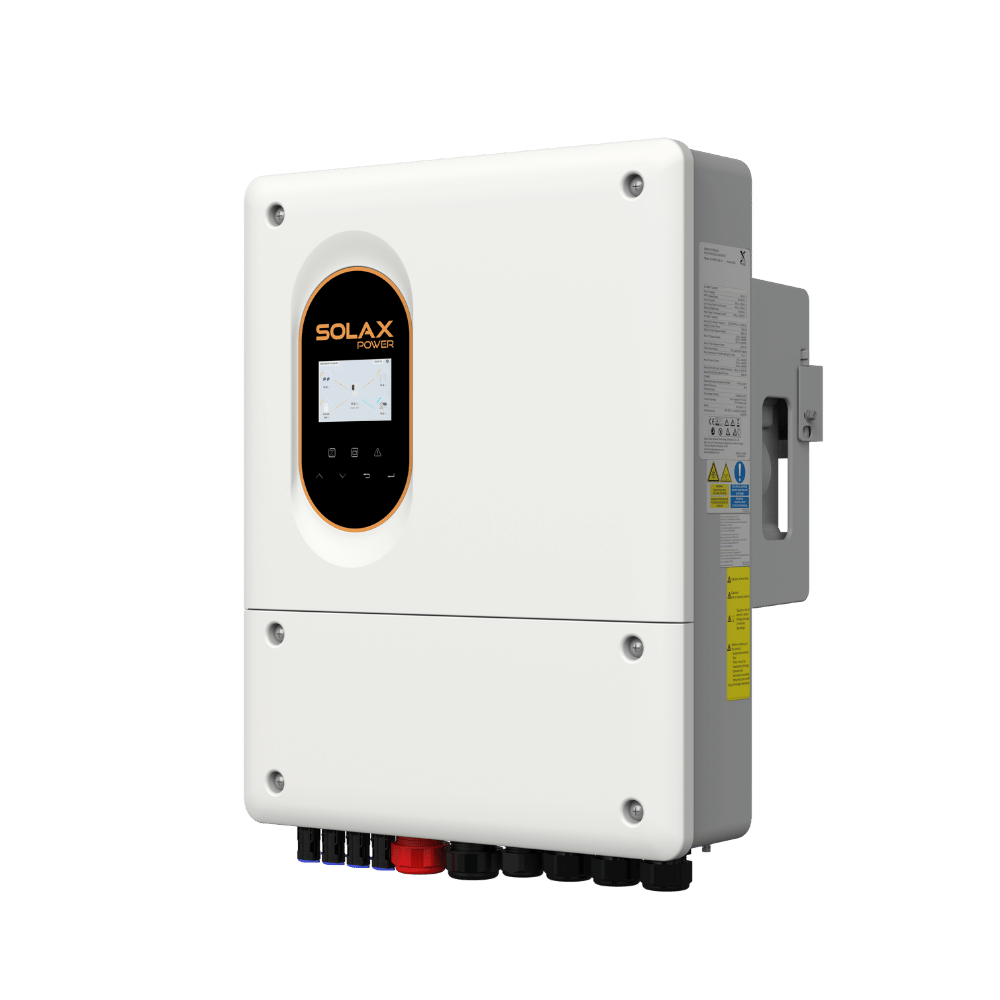

The bess container is the foundational physical unit for utility-scale deployment. The SolaX ORI Liquid Cooling ESS System is designed as a Utility All-In-One ESS, that is engineered for both high-performance and accelerated deployment. The ORI combines the 2.5 MW PCS and the 5.015 MWh battery system in a containerized design, mitigating the risks and delays typically associated with multi-vendor, field integration.

A crucial aspect of the ORI's performance is its thermal management. As a Liquid Cooling ESS System, it ensures High Efficiency by maintaining exceptional thermal stability, achieving ≤3°C temperature uniformity across the battery cells,. This precise thermal control maximizes energy throughput, minimizes degradation over the asset's multi-decade lifespan, and is crucial for maintaining predictable revenue streams in harsh outdoor environments.

Best for: Utility projects requiring predictable, sustained high power (kW) delivery and maximum energy utilization (kWh) over the asset's life.

Performance Win: Optimal thermal management reduces the reliance on ancillary power (fans/HVAC) and minimizes energy loss.

Trade-off: High controls quality and initial integration effort are required, but this is offset by high efficiency and reduced on-site complexities.

5) Accelerating Deployment with Factory Pre-assembly and Pre-commissioning

Deployment speed is a core competitive advantage in modern utility markets. The primary challenge for EPCs is minimizing high-risk, time-consuming on-site work—particularly the time between equipment delivery and achieving Utility PTO (Permission to Operate).

The most effective strategy to overcome this is the Factory Pre-assembly and modular design approach. SolaX implements this with the ORI system through pre-installed components and factory pre-commissioning. This proactive factory preparation significantly shortens complex on-site installation and extensive debugging. This preparation enables rapid deployment and directly contributes to the goal of grid connection in as little as 15 days. By transferring commissioning risk from the field back to the controlled factory environment, the project's critical path is substantially compressed.

Best for: Utility projects facing aggressive interconnection deadlines, high site labor costs, and a high volume of modular units.

Operational win: Accelerates the asset's contribution to grid stability and drastically shortens the time-to-revenue.

Common pitfall: Failing to coordinate tightly between the factory engineering and site preparation teams, leading to missed dependencies upon delivery.

6) Comprehensive Forecasting and Integrated Control Systems

For a utility ESS to operate profitably and efficiently without requiring constant manual intervention, forecasting and deeply integrated controls are mandatory. Forecasting utilizes various data streams—including market predictions, grid status updates, and day-ahead rules—to anticipate optimal charging and discharging windows.

The control system then translates that complex forecast into deterministic actions: dispatching the battery, managing the PCS, and enforcing operational limits. For the SolaX Utility-Scale Solution ORI, this is facilitated by its Smart Energy Management capability and integration with platforms like SolaXCloud and potentially VPP (Virtual Power Plant). The final, critical step is continuous commissioning—the ongoing verification that all telemetry (sensors, meters) remains accurate, control logic is aligned with the latest ISO/Utility requirements, and the system performs reliably, even during high-variability or chaotic grid events.

Best for: Utility plants aiming for high, repeatable automation and sustained profitability.

Operational win: Ensures sustained efficiency and reduced risk during volatile market or grid events.

Trade-off: Requires a high initial integration effort between the asset controls, SCADA, and market management systems.

SolaX ORI Product Specification Summary

The ORI system is a purpose-built Utility All-In-One ESS, designed to simplify deployment and maximize performance through integration. The system combines high-quality LFP battery cells and advanced liquid cooling with a containerized PCS.

Parameter | ORI-P2500 (PCS Unit) | ORI-B5015L-2H (Battery Unit) |

Rated AC Power | 2500 kVA | N/A |

Rated Energy Capacity | N/A | 5015 kWh |

Max. DC Voltage | 1500 V | N/A |

| Cooling Method | N/A | Liquid cooling |

Thermal Uniformity | N/A | ≤3°C |

PCS Max. Efficiency | 99% (or 99.04%) | N/A |

Design | Containerized (6058 x 2896 x 2438 mm) | Containerized (6058 x 2896 x 2438 mm) |

Utility ESS Selection Guide

Choosing the right ESS configuration depends critically on the project's specific revenue streams, the technical constraints of the grid, and the logistical realities of the deployment site. This guide focuses on solutions provided through Utility-Scale Plant Solutions,.

Factor 1: Solution Integration and Fast Deployment Capacity

Utility projects must prioritize systems that fundamentally minimize complexity in the field. The ORI systems one-stop solution—combining PCS and battery in a single container and utilizing factory pre-commissioning—is designed precisely to mitigate the risks and costly delays associated with multi-vendor sourcing and complex on-site integration. This capability is what enables the goal of grid connection in as little as 15 days.

Factor 2: High Efficiency and Thermal Uniformity

Revenue stability in utility ESS is highly sensitive to efficiency, as any energy loss directly impacts profitability. Developers should seek solutions with proven capabilities:

PCS Efficiency: The ORI offers a high-efficiency 99.04% PCS.

Cooling Method: Liquid cooling is superior for utility applications because it effectively manages internal heat, maintaining ≤3°C temperature uniformity. This consistent thermal control reduces operational energy demands, lowers maintenance costs, and minimizes cell degradation over the project lifespan.

Factor 3: Power (kW) vs. Energy (kWh) Configuration

The specific utility application dictates the appropriate sizing. While energy density is a concern, the system must first be correctly sized for the required power delivery (kW) to meet essential grid service contracts. The ORI system provides flexible capacity configuration (2.5/5/7.5MW), allowing projects to match power and energy requirements precisely and avoid unnecessary over-sizing.

Conclusion

Success in deploying utility-scale ESS depends on disciplined execution of key strategies: prioritizing high-efficiency thermal management, integrating rapid deployment features, and ensuring robust, coordinated system controls. The SolaX ORI Liquid Cooling ESS System provides a powerful foundation for Utility-Scale Plant Solutions, by addressing these factors directly. By leveraging its containerized design, factory pre-commissioning, and ≤3°C temperature uniformity, EPCs can achieve operational excellence, deliver systems quickly, and ensure maximum energy utilization for profitable grid services. The plants that excel in this growing market will be the ones that can reduce deployment complexity reliably without sacrificing performance or grid stability.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms