December 31, 2025

Choosing the Best Utility-Scale Energy Storage for Maximum Energy Security

Share my #SolaXStory

Introduction: The Utility-Scale Energy Security Imperative

Utility-scale bess container projects are increasingly being evaluated not just as "more storage," but as hard infrastructure critical for energy security: they help grids ride through outages, smooth volatility from renewables, and reduce the operational risk that comes from fuel supply constraints and transmission congestion.

In practice, a well-designed bess container deployment transforms storage into a controllable, dispatchable asset—one that can respond in milliseconds, support black-start strategies, and provide resilient capacity when conventional generation is stressed. The economic case for energy security is now undeniable. IRENA reports that renewables and storage avoided $467 billion in fossil fuel costs in 2024 alone. With 91% of new utility-scale renewable projects now cheaper than fossil fuel alternatives(IRENA - Renewable Power Generation Costs in 2024), high-efficiency systems like the SolaX ORI—boasting a high efficiency rate—are the primary drivers of this global shift toward affordable, sovereign energy.

In this environment, procurement conversations have matured, with buyers demanding specific answers regarding safety layers, failure containment, factory pre-commissioning, and lifecycle degradation—factors that determine whether grid scale battery storage delivers "nameplate" capability in the field. These concerns drive explicit requirements for interconnection readiness, protection coordination, controls/SCADA integration, and realistic availability targets.

In this environment, procurement conversations have matured, with buyers demanding specific answers regarding safety layers, failure containment, factory pre-commissioning, and lifecycle degradation—factors that determine whether grid scale battery storage delivers "nameplate" capability in the field. These concerns drive explicit requirements for interconnection readiness, protection coordination, controls/SCADA integration, and realistic availability targets.

This guide explains how to choose utility-scale energy storage for maximum energy security, covering critical considerations such as sizing, siting, design architecture, safety, controls, and decision frameworks. Throughout, we reference SolaX Power's ORI Liquid Cooling ESS System as a practical example of how modern, containerized systems are packaged and operated for large-scale deployments.

Core Foundations of Utility Energy Security

Energy Security: Reliability, Resilience, and Sovereignty

Energy security at the grid scale is a blend of reliability (keeping the lights on during normal operations), resilience (recovering quickly from disruptions), and sovereignty (reducing exposure to single points of failure—such as fuel, imports, or constrained corridors). Utility-Scale Plant Solutions contribute to all three, provided the design is tailored to the specific threats faced by the grid. For instance, a storm-prone coastal area may prioritize islanding, black-start support, and hardened communications, while a solar-dominated region may focus on evening ramping and contingency reserves. The scale of the energy security challenge is immense: the IEA reports that the transition to a low-carbon energy system requires systemic changes and innovative solutions to meet the increasing demand for clean, secure, and reliable power(IEA - Batteries and Secure Energy Transitions - Special Report, April 2024).

A practical method for translating energy security into storage requirements is to list specific "security events": the top five outage drivers, the largest single contingency, and the most frequent operational constraints. Success is then defined in operational terms: hours of duration, required megawatts, and necessary response time. This framework ensures the bess container project is sized not just for energy arbitrage, but to maximize its resilience value.

Grid Services: What Storage Really Does for the System

Utility storage provides essential grid services, including capacity, operating reserves, frequency response, ramping support, congestion relief, voltage support, and renewable firming. A key benefit is that many of these services can be stacked—allowing the same grid scale battery storage asset to improve day-to-day stability while simultaneously reducing blackout risk.

However, successfully stacking services requires explicit operational discipline. Dispatch priorities must clearly define what portion of state-of-charge (SoC) is reserved for contingencies, how quickly the SoC must be restored, and what operational constraints apply (such as temperature limits, cycle limits, and interconnection export limits). If these rules are ambiguous, projects may underdeliver during stressed conditions—the exact moment when energy security is paramount.

The Containerized ESS (BESS Container) and Modularity

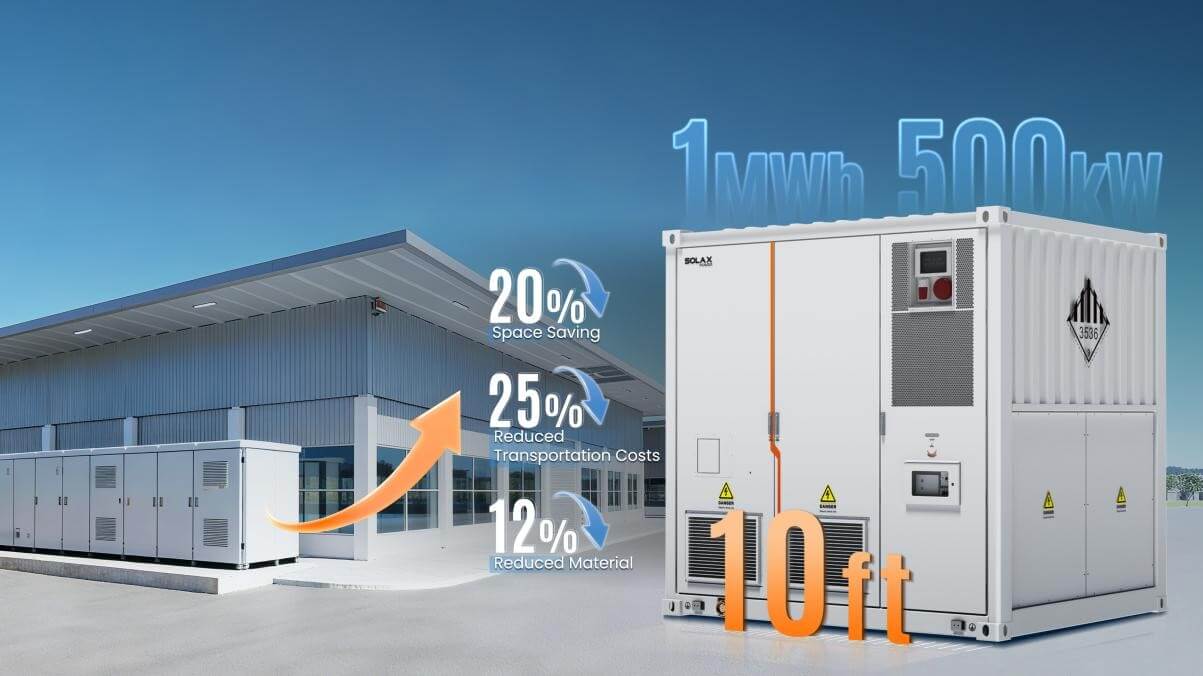

A bess container is a modular enclosure that integrates battery racks, thermal management (liquid cooling is common), protection, safety systems, auxiliary power, and internal controls that coordinate with higher-level EMS/SCADA. Containerization is vital for utility projects because it standardizes factory build quality, significantly reduces on-site labor requirements, and improves long-term maintainability, particularly when scaling to hundreds of megawatt-hours.

From an energy-security viewpoint, modularity acts as a risk-control tool. It enables superior compartmentalization, allows for the faster replacement of failed subsystems, and ensures clear fault isolation. Furthermore, containerized platforms, such as the ORI Liquid Cooling ESS System, improve performance predictability by precisely controlling temperature gradients—a major contributor to uneven aging and capacity loss.

Storage Taxonomy: Duration, Power, and Chemistry

Utility storage projects are defined by three main choices: power (MW), energy (MWh), and chemistry/thermal design. Duration is the simple ratio of energy divided by power. The choice of chemistry and cooling profoundly influences the system's safety, efficiency, and degradation characteristics. Lithium iron phosphate (LFP) is the dominant choice for stationary utility deployments due to its favorable thermal stability and long cycle life.

Table 1: Utility Deployment Challenges and the ORI Solution

Utility-Scale Challenge | Definition in Security Terms | ORI Feature Solution |

Interconnection Delays | Risk of schedule creep and missed PTO targets | Factory pre-commissioning for grid connection in as little as 15 days |

Thermal Degradation | Capacity loss and derating under high ambient temperature | Liquid Cooling ensuring ≤3°C temperature uniformity |

Grid Compliance/Safety | Uncontrolled failure spread and electrical spikes | Collaborative Protection with 4-layer fuse protection |

Maintenance Downtime | Reduced availability during repair events | Rapid maintenance approach (e.g., 1-hour part replacement) |

Revenue Optimization | Maximizing energy throughput and utilization | High-efficiency 99.04% PCS and Intelligent clusters |

Architecture and System Design for Energy Security

A bess container architecture is a layered system designed to tolerate internal faults without escalating into plant-wide outages. At the utility scale, design must prioritize fault containment, long-term maintainability, and clarity of protection zones.

Start by establishing the container layout and redundancy philosophy. Engineers must determine the maximum credible failure within one compartment and the specific physical and active controls that prevent its propagation. Strong designs mandate the separation of battery compartments, the integration of layered detection and suppression systems (such as fire-resistant compartments), and clear pathways for isolating strings or clusters without shutting down the entire plant. Energy security is significantly enhanced when partial operation is possible—because 60–80% deliverability during a disturbance is vastly superior to a full outage.

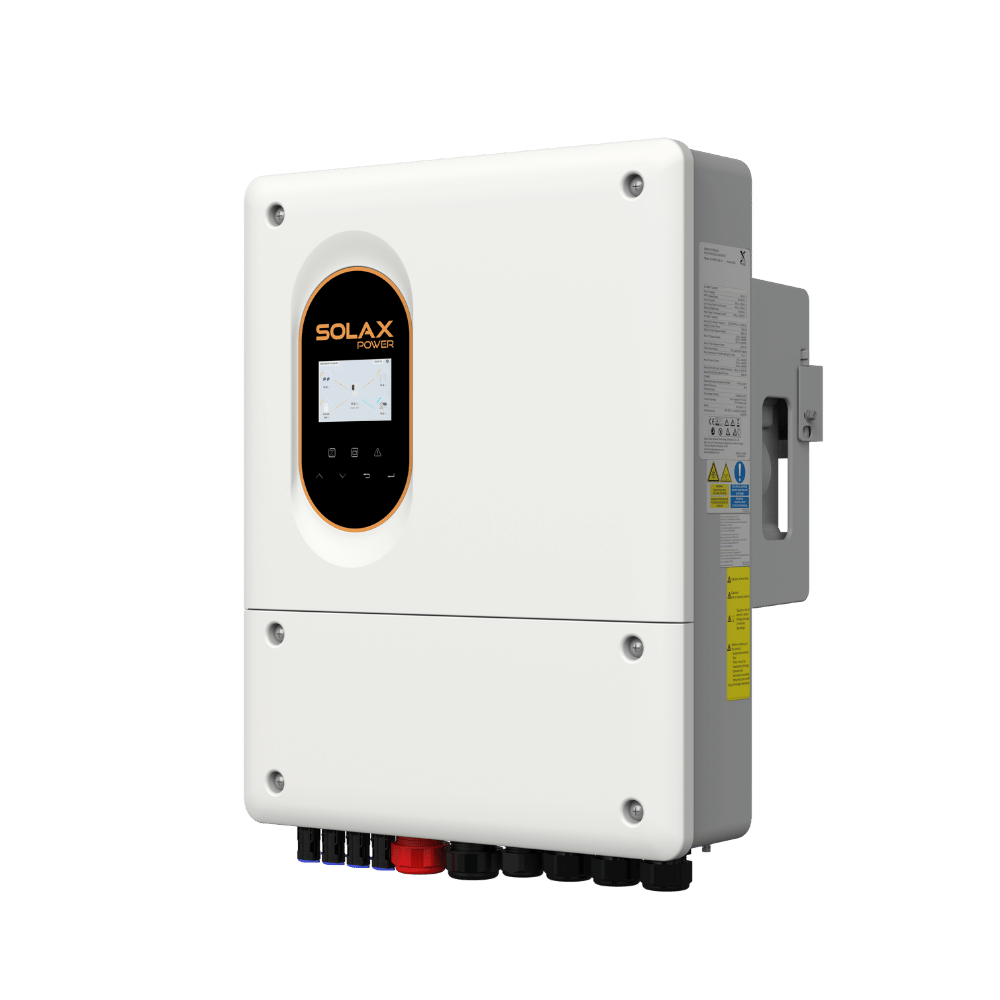

Next, the electrical flow must be carefully mapped: battery DC to PCS, PCS to transformer, transformer to MV collection, and finally to the Point of Interconnection (POI). The choice of the PCS (Power Conversion System) dictates the plant's ability to support crucial grid functions like reactive power support and ride-through behavior. The SolaX ORI Liquid Cooling ESS System is a containerized solution that integrates a 2.5 MW PCS with a 5.015 MWh battery system, featuring variants with high DC-side voltages (up to 1500 V) and MV voltage ranges (6–35kV depending on configuration), which are essential details for utility integration and protection coordination.

Finally, design must account for maintainability and time-to-repair. A plant intended for energy security must remain serviceable even under adverse conditions (e.g., extreme heat, limited access). Clear labeling, consistent modules, and a solid spares strategy (covering contactors, sensors, and pumps) directly influence availability. SolaX notes a target of "1-hour part replacement" in its ORI product advantages, reflecting the industry best practice of minimizing Mean Time To Repair (MTTR) in utility programs.

Technology and Thermal Strategy: Liquid Cooling for Deliverability

Industry forecasts project that the liquid cooling market for stationary BESS will grow to $30.2 billion by 2034 as developers demand superior temperature uniformity for high-density projects. SolaX’s ORI system is at the forefront of this trend, utilizing advanced liquid cooling to maintain cell temperature differences within ≤3°C, effectively extending battery lifespan and ensuring safety beyond the capabilities of traditional air-cooled alternatives(Insightace Analytic - Liquid Cooling Market for Stationary BESS Report).

LFP systems are often paired with liquid cooling, which is highly effective because it reduces cell-to-cell temperature spread. This reduction in thermal gradients is critical, as it supports uniform aging and prevents the unexpected capacity loss or aggressive derating that can compromise energy-security performance during high-temperature conditions.

The ORI Liquid Cooling ESS System emphasizes this principle by employing advanced liquid cooling to achieve ≤3°C temperature uniformity. This level of thermal precision, combined with an optimized low-flow resistance pipeline design, helps maintain uniform cooling with minimal parasitic energy consumption. This Innovative Energy Savings approach, coupled with the high-efficiency 99.04% PCS, lowers operational costs while maximizing overall energy efficiency.

Table 2: SolaX ORI Utility ESS Key Technical Specifications

| Component/Feature | ORI-P2500 (PCS Unit) | ORI-B5015L-2H (Battery Unit) |

System Type | Utility All-In-One ESS | Utility All-In-One ESS |

Rated AC Power | 2500 kVA | N/A |

Rated Energy Capacity | N/A | 5015 kWh |

PCS Max. Efficiency | 99% (or 99.04%) | N/A |

| Max. DC Voltage | 1500 V | 1500 V |

Cooling Method | N/A | Liquid cooling |

Thermal Uniformity | N/A | ≤3°C |

Deployment Time Goal | Factory pre-commissioning | Grid connection in as little as 15 days |

Sizing, Siting, and Interconnection

Sizing a bess container project for energy security is a nuanced process. While power (MW) dictates instantaneous capability and energy (MWh) dictates duration, security-oriented sizing adds crucial layers: deliverability (what can actually be exported under interconnection limits and ambient conditions) and availability (what fraction of the fleet is expected to be online during stress events). The challenge for utility-scale security isn't just technology; it's time. According to Lawrence Berkeley National Laboratory (LBNL), the backlog of projects waiting to connect to the grid reached a staggering 2,300 GW by the end of 2024, with median wait times doubling to over four years(Lawrence Berkeley National Laboratory (LBNL) - Queued Up: 2025 Edition). In this bottlenecked environment, the SolaX ORI’s rapid 15-day on-site commissioning is not just a convenience—it is a critical strategic advantage for developers needing to meet strict interconnection windows.

A practical sizing workflow involves:

Defining the security objective in operational terms (e.g., "cover the largest contingency for 30 minutes").

Converting the objective into required MW and MWh, adding a necessary reserve margin for derating and degradation.

Deciding the SoC management strategy (fixed reserve vs. dynamic reserve based on forecasts).

Validating interconnection capacity: confirming the system can deliver the required MW at the POI during peak temperature, minimum voltage, and worst-case protection constraints.

Interconnection is frequently the hidden constraint. A common failure mode is where a perfectly sized battery is curtailed by export limits, insufficient transformer capacity, or protection settings. EPCs must treat interconnection milestones as a core risk stream, aligning inverter ride-through settings with the grid code, and confirming reactive power requirements early in the project life cycle.

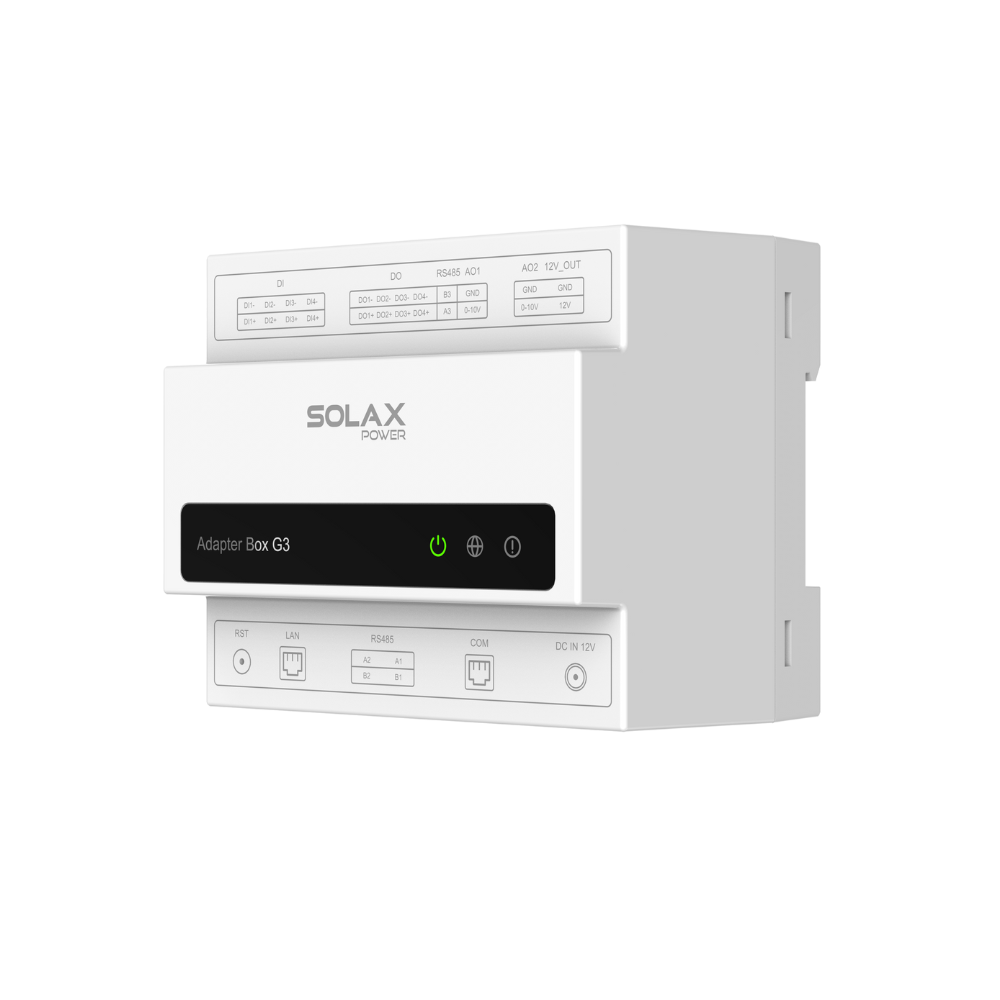

Controls, Monitoring, and Optimization

Controls dictate whether grid scale battery storage functions as dependable, resilient infrastructure or as a fragile, operator-dependent asset. Utility storage requires robust EMS logic, plant controller coordination, and SCADA integration. For energy security, the bar is raised: autonomous operation modes are needed to protect reserves, manage thermal limits, and maintain stable grid behavior even when communications are degraded.

The control architecture must enforce an EMS hierarchy. The BMS ensures cell safety at the lowest level. The PCS/controller executes power commands and ride-through functions. The top-level EMS optimizes dispatch based on market signals and forecasts. A strong architecture avoids "conflicting brains," which can lead to unnecessary derates or SoC drift. SolaX solutions support this integration via Smart Energy Management features like SolaXCloud and VPP capability.

Cybersecurity is now inseparable from operational security. Access control, secure remote updates, encrypted communications, and monitoring for anomalies are essential requirements. SolaX positions SolaXCloud as a real-time monitoring and energy management layer, which acts as the "system of record" for availability, event response, and warranty-relevant operating conditions. This is crucial for meeting higher cyber and regulatory expectations.

Forecasting integration is another key lever. When the EMS understands load, renewable output, and price signals, it can effectively preserve enough SoC for contingencies without leaving commercial value on the table, preventing "empty battery" incidents during peak demand.

Selection, Best Practices, and Bankability

Safety Design and Thermal Runaway Mitigation

Safety must be evaluated as a layered system: chemistry, thermal management, detection, suppression, compartmentalization, ventilation, and emergency procedures. The key question is: "When something fails, does it stay local and controllable?". Vendors must provide clear descriptions of fault isolation and demonstrate how thermal management (like the ORI's liquid cooling) and alarms propagate to the plant controller to trigger operational limits or shutdowns.

It is essential to verify how the system derates under heat and after repeated high-power events. A plant that derates heavily at high ambient temperatures may underdeliver precisely when the grid is most stressed.

Bankability and Verification

Bankability relies on verifiable proof: factory testing, performance guarantees, warranty terms, and documentation quality. For energy security projects, require acceptance testing that validates critical performance metrics: response time, ramp rate, sustained output, and recovery behavior after faults. This ensures that grid scale battery storage delivers true deliverability, not just nameplate capacity.

Table 3: Utility ESS Selection Decision Matrix (Security Focused)

| Decision Scenario | What to Prioritize | Recommended Approach (ORI/Containerized) | Key Trade-offs |

Peak Capacity + Contingency Reserve | Deliverable MW at POI, SoC reserve rules, availability | Favor standardized bess container blocks with clear partial-operation modes | May reduce cycling revenue if reserve floors are strict |

High-Heat Region with Frequent Peaks | Thermal uniformity, derating curves, long-term degradation | Utilize Liquid Cooling (e.g., ORI's ≤3°C uniformity) and conservative temperature limits | Higher complexity in cooling O&M |

Resilience for Critical Infrastructure | Islanding strategy, black-start integration, comms hardening | Define microgrid control modes, verify full protection coordination | More complex commissioning and specialized testing required |

Best Practices and Pitfalls

Critical Best Practices

Standardize BESS Container Modules: Standardizing modules (like the ORI container block) reduces spare parts diversity, shortens training time, and makes performance across a fleet more predictable.

Validate Security Behaviors: Specify a testing and acceptance plan that validates contingency reserve logic, ramp-rate compliance, sustained discharge at high temperature, and fault recovery.

Design for Maintainability: Require clear maintenance clearances and service-friendly component placement. Time-to-repair is a resilience KPI.

Treat Controls and Cybersecurity as Core Engineering: Define telemetry, data latency, and access-control models early.

Common Pitfalls to Avoid

Ignoring Interconnection Constraints: Export limits and protection coordination can cap deliverable MW. Engage the interconnecting utility early.

Under-specifying Safety Layers: Ensure layered safety (chemistry, thermal, detection, compartmentalization).

Skipping Lifecycle Degradation Modeling: Model degradation based on the expected duty cycle to ensure the asset does not fall below security requirements prematurely.

Over-optimizing for Single Revenue Streams: Define "reserve first" dispatch rules when energy security is the primary value driver to prevent starving contingency reserves.

Conclusion

Choosing utility-scale storage for energy security means treating a bess container project as critical infrastructure: design for fault containment, maintainability, deliverability at the POI, and secure controls. The most successful outcomes are achieved by aligning grid services to clear dispatch logic, sizing to meet real resilience hours, and validating interconnection and testing plans early.

The SolaX ORI Liquid Cooling ESS System provides a robust platform for Utility-Scale Plant Solutions, by integrating high-efficiency components, ensuring ≤3°C temperature uniformity, and reducing deployment timelines through factory pre-commissioning. As grid scale battery storage continues to scale, the winning projects will be those that pair standardized container platforms with operational discipline and verified performance.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms