January 30, 2026

How to Future-Proof Your Business with Scalable MWh Energy Solutions

Share my #SolaXStory

Rising demand charges, operational downtime risk, and a variable electricity tariff environment are pushing more facilities teams to rethink how they buy, use, and back up energy.

A future-proof approach pairs commercial solar systems with a solar battery storage system and a strategy for EV charging that can grow with your fleet. Instead of treating PV, storage, and charging as separate projects, you design a single architecture where the inverter smart layer, monitoring, and protection scheme are ready for expansion.

To see how this looks in a real portfolio, start with SolaX Power C&I solutions.

How to Future-Proof Commercial Solar Systems

Step 1: Define load, tariff, and risk goals

Before selecting equipment, quantify the problem you are solving. Pull at least 12 months of interval data if possible, then map three baselines: average kW, peak kW (demand), and daily or weekly kWh patterns.

Next, translate your variable electricity tariff into design requirements. Identify the utility demand charge window, time-of-use periods, and any export limits that might cap PV output.

From there, set measurable goals such as a peak demand reduction target (kW), a backup runtime for critical loads (hours), and a minimum PV self-use rate. These numbers keep your EPC and your internal stakeholders aligned, and they prevent overbuilding a commercial battery storage system that does not match your actual operating profile.

Step 2: Choose the right architecture for PV, ESS, and EV charging

A future-proof architecture is one that supports phased upgrades. Start by deciding how PV and storage will interact at the power-conversion layer. In many commercial solar systems, PV is handled by a string inverter, while storage uses a dedicated PCS or storage inverter. In other designs, a hybrid solar inverter approach can simplify coordination by keeping PV and battery control in one platform.

Then layer in EV charging the right way. If you expect fleet electrification, treat EV charging as a controllable load from day one, even if you install chargers later. Plan spare electrical capacity, conduit paths, network drops, and a control strategy that can prioritize site loads versus charging loads.

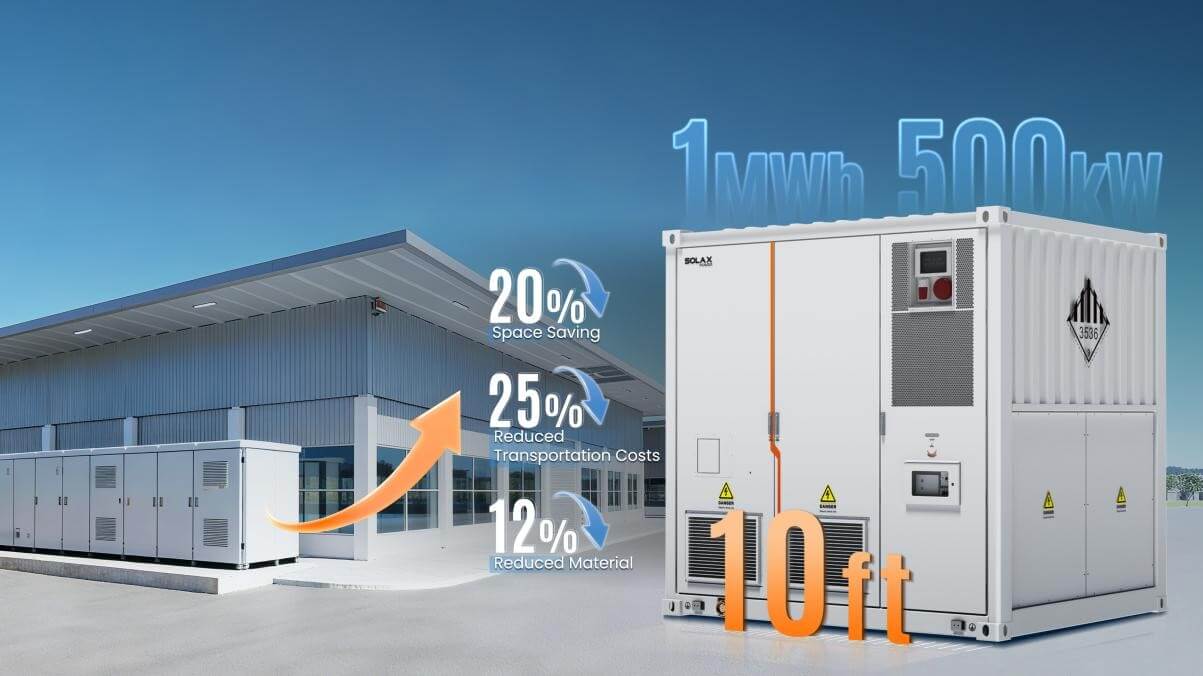

Step 3: Select scalable C&I ESS blocks you can expand to MWh

When you want MWh scale, the easiest mistake is choosing storage that cannot be expanded cleanly. You want modular blocks that can be added without changing your entire switchgear lineup or communications topology.

The SolaX ESS-TRENE Liquid Cooling system is designed as a C&I energy storage block, with a 125 kW / 261 kWh configuration and models such as TRENE-P125B261L-E and TRENE-P124B261L-E. It uses an LFP battery with a 314 Ah cell specification, rated battery voltage of 832 V, and an operating temperature range of -30 to 55 C (with derating above 45 C).

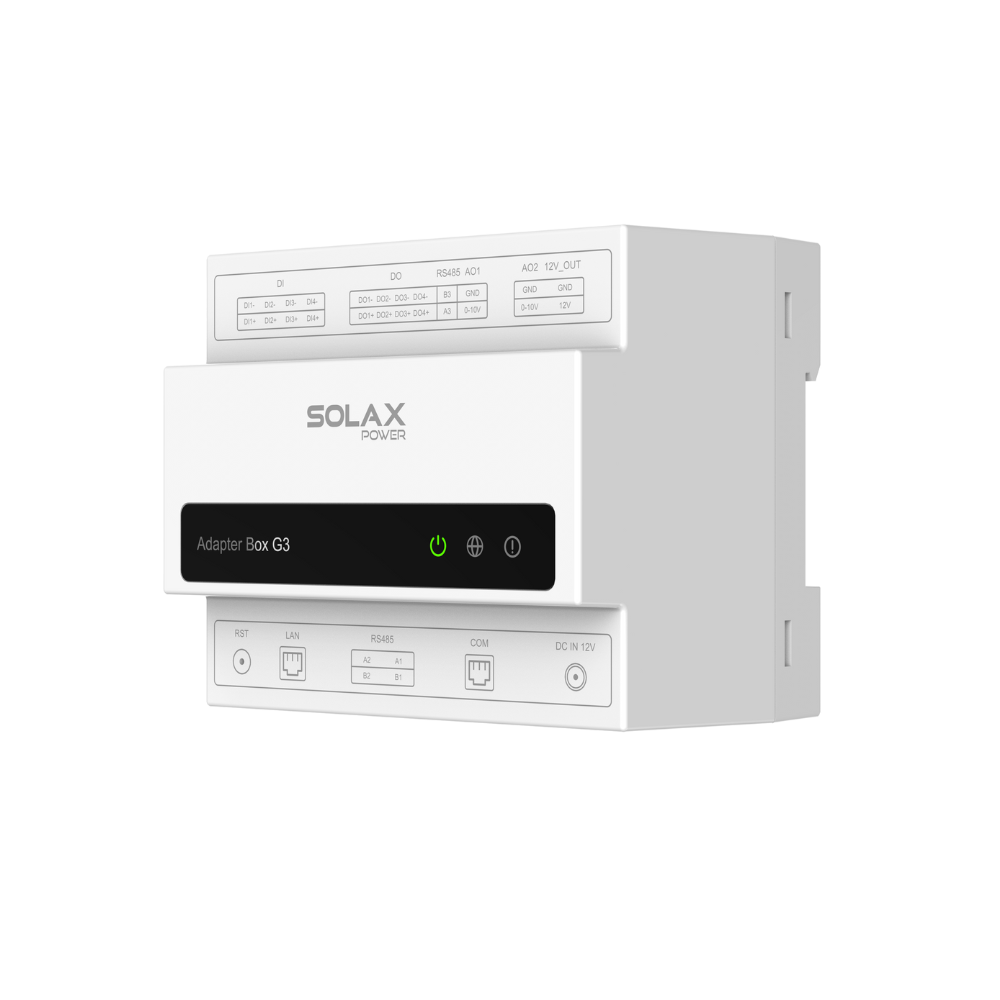

Step 4: Plan controls for EMS, monitoring, and vpp electricity readiness

As projects scale, the control layer becomes your real differentiator. The hardware can store energy, but the EMS decides when to charge, discharge, limit export, or preserve backup reserve.

Start by defining your control priorities:

(1) protect critical loads,

(2) cap peak demand,

(3) maximize PV self-use,

(4) optionally provide grid services.

This ordering matters because an aggressive peak shaving schedule can conflict with resilience if you drain batteries right before an outage.

Step 5: Engineer interconnection, metering, and protection early

Interconnection delays can kill project momentum, especially when you scale from commercial solar power to battery storage utility scale thinking. Start with a single-line diagram that clearly shows the PCC, main service, PV, ESS, and any EV charging distribution.

According to OSHA guidance under 29 CFR 1910.147, lockout is generally the preferred method over tagout for ensuring de-energization, and programs must be enforced and supported by training. That is directly relevant during commissioning and maintenance of inverters, switchgear, and battery enclosures(OSHA).

Step 6: Commission, test, and optimize schedules over the first 90 days

Commissioning is where future-proofing becomes measurable. Start with functional tests: PV production verification, inverter communication checks, ESS charge and discharge validation, and alarms.

Then perform mode-based testing. For peak shaving, test that the discharge setpoint tracks demand without oscillation. For backup, confirm critical load transfer logic and verify runtime assumptions with a controlled test at representative load.

Adapting Commercial Energy Storage in Different Scenarios

Manufacturing (peak shaving plus backup)

Focus on protecting critical process loads and limiting demand spikes from motors and process equipment. Use a higher minimum reserve threshold so your commercial energy storage is not drained during production peaks right before an outage. In this scenario, the inverter storage control strategy should prioritize stability over maximum arbitrage.

Retail (PV self-use plus demand control)

Retail loads often peak with HVAC and lighting during business hours, which aligns well with PV. Emphasize commercial solar systems sizing for self-consumption and use storage to flatten the late afternoon ramp. Small schedule tweaks can materially improve performance under time-of-use rates.

Fleet depot (solar powered ev charger focus)

Treat charging as a dispatchable load. Use charging windows that align with PV output, then use storage to bridge short gaps. If the depot will grow, plan for more chargers and higher service capacity now so adding additional solar electric car charger ports later does not require new trenching.

Microgrid-ready sites (grid-tied plus islanding plan)

If resilience is a priority, design for islanding even if you start grid-tied. Include space and pathways for switching equipment, and validate that control, metering, and communications will support islanded operation. This is often where a hybrid solar inverter strategy can simplify coordination, provided it meets your power and redundancy needs.

What You Will Need Before You Start

Required Tools and Materials

12 months of interval load data: Minimum 15-minute data is ideal for accurate peak demand modeling and commercial energy storage sizing.

Tariff documentation: Include demand charge windows, time-of-use periods, and export rules for your variable electricity tariff modeling.

Site single-line diagram and as-builts: Needed for interconnection, protection coordination, and expansion planning.

PV layout and shading constraints: A PV design that supports future expansion avoids rework when you grow beyond the first phase.

Communications plan: Network connectivity is mandatory for cloud monitoring and for any future vpp electricity participation.

Qualified EPC and commissioning plan: Choose teams experienced in commercial and industrial solar deployments and battery commissioning.

Troubleshooting Guide

Problem | Cause | Solution |

Low savings after commissioning | Schedule does not match demand peaks or TOU windows | Re-tune EMS time windows using interval data; set discharge to target the top 1-2 hours of daily peak demand first, then expand to secondary peaks. |

PV curtailment during sunny hours | Export limit or inverter setpoints forcing zero-export | Adjust export control setpoints and meter placement; if curtailment persists, add storage capacity or shift flexible loads such as EV charging into midday. |

ESS alarms during hot weather | Thermal management constraints or site airflow issues | Verify liquid cooling operation and cabinet clearances; reduce charge/discharge power above derating thresholds and confirm ambient conditions stay within rated limits. |

Battery state of charge swings too fast | Aggressive peak shaving or EV charging priority conflicts | Add minimum reserve thresholds, cap ramp rates, and smooth EV charging profiles so the system does not chase short spikes. |

Monitoring gaps or delayed data | Network instability or misconfigured gateway | Improve network uptime with wired connections where possible, segment OT traffic, and verify time sync and gateway configuration before blaming the inverter smart layer. |

Conclusion

Future-proofing commercial solar power is about building an expandable platform, not just installing hardware. Start with clear load and tariff goals, then design an architecture where PV, storage, and EV charging share a control strategy that can grow to MWh scale. Modular blocks like an all-in-one solar energy storage system make expansion easier, while strong monitoring and standards-based controls keep your options open for grid services and vpp electricity participation.

If you want a practical starting point for C&I energy storage planning, explore SolaX commercial and industrial solar solutions and partner with us to map your first block to a clear expansion roadmap.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms