February 12, 2026

Top ESS for Solar-Powered Agricultural Applications: Real-World Case in Bavarias Egg Processing Center

Share my #SolaXStory

Agricultural facilities depend on nonstop solar energy supported by storage because one outage can spoil product, stop processing, or break cold-chain continuity. That is why many sites are moving from a basic solar power system to a full energy storage system (often called a BESS battery or solar energy storage system) with fast backup switching and real monitoring.

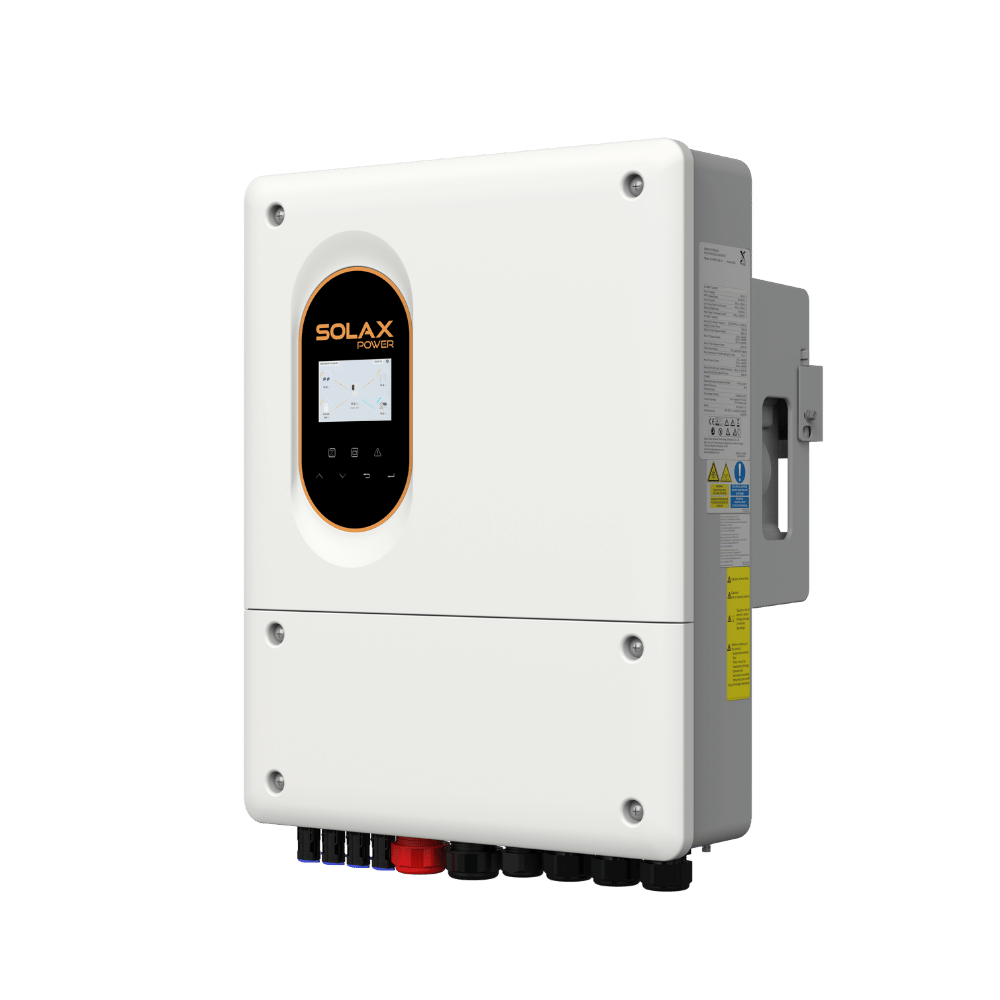

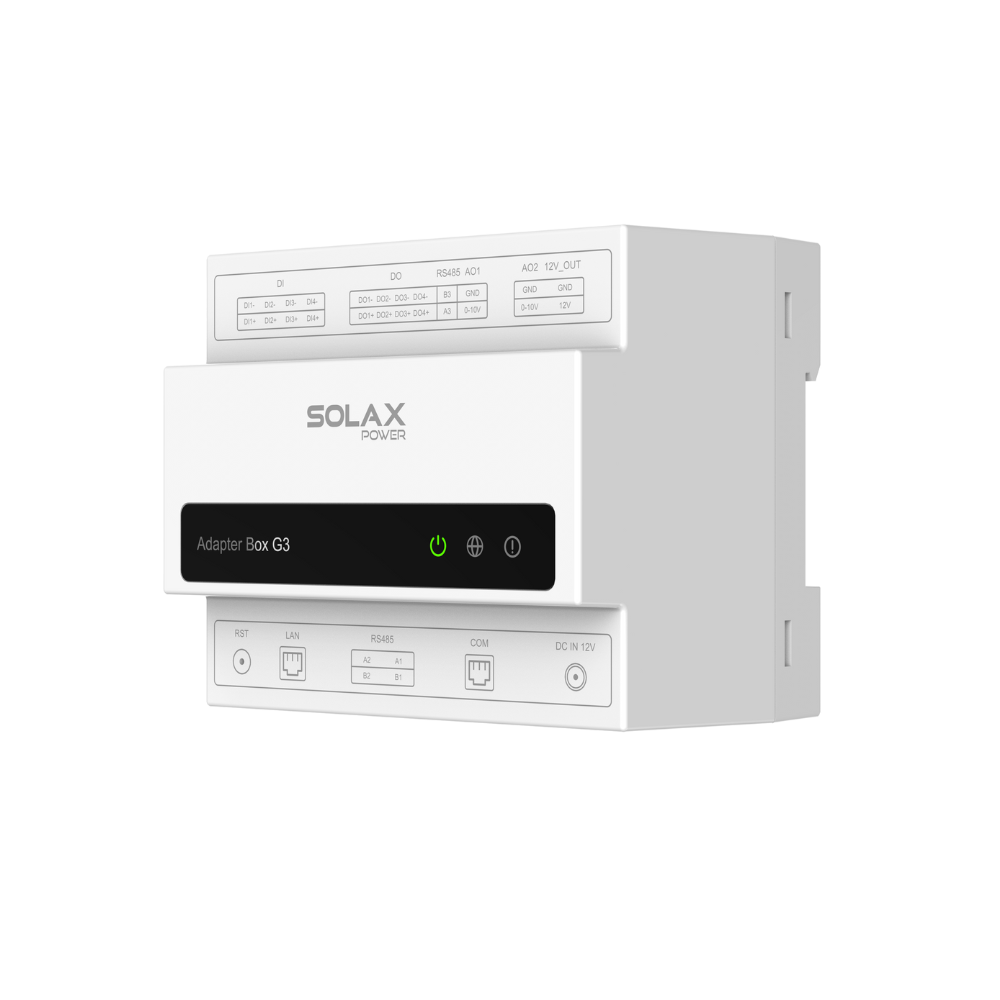

This how-to guide shows how to choose and set up an ESS for agricultural operations using a real-world C&I example from Bavaria, Germany: an egg sorting and packaging center that needed extremely high power continuity for cold-chain logistics. In that project, the site used a SolaX TRENE system with an emergency switching device designed for \< 200 ms transfer.

Choose an ESS for Agricultural Solar PV

1 Audit agricultural loads and downtime

Start by listing every load that must keep running during grid loss. In agricultural processing, the most important loads are often not the biggest loads.

Use this quick method:

Group loads by process: cold rooms, compressors, pumps, sorting lines, packaging, lighting, IT, and security.

Mark each load as Critical (must run), Important (should run), or Flexible (can shut off).

Define downtime tolerance in minutes. Cold-chain loads may need near-zero interruption.

Then translate the audit into two sizing numbers:

kW for continuity (instant power needed during outage).

kWh for autonomy (how long you need that power).

In Bavaria, the case highlights cold-chain logistics and processing continuity as the driver, which is a classic reason to invest in a properly sized inverter battery and not just PV.

2 Define solar PV and ESS goals

Clear goals prevent overbuilding and help you compare options across solar energy companies. Write goals as measurable targets.

Common goals for agricultural C&I sites:

Peak shaving: reduce demand spikes during cleaning cycles, compressors, or batch processing.

Backup: keep critical circuits energized during outages.

PV self-consumption: store mid-day solar PV surplus for evening processing.

Demand response: allow the EMS to limit peaks or shift loads.

Tie each goal to a control strategy:

Peak shaving needs fast power response and accurate metering.

Backup needs a defined critical-load panel and fast transfer switching.

PV optimization needs scheduling and monitoring.

SolaX positions its C&I ESS as a smart energy platform with advanced EMS and PCS for real-time monitoring and smart scheduling, which fits these goal types.

3 Right-size C&I all-in-one ESS

Right-sizing is about matching power (kW) and energy (kWh) to your real load shapes. A common mistake is sizing only by total monthly kWh.

Use a simple 3-step calculation:

Determine the highest critical-load kW you must cover during an outage.

Multiply by required runtime hours to get minimum critical-load kWh.

Add a margin for motor starts, temperature derating, and future expansion.

A practical example from the SolaX C&I all-in-one ESS lineup:

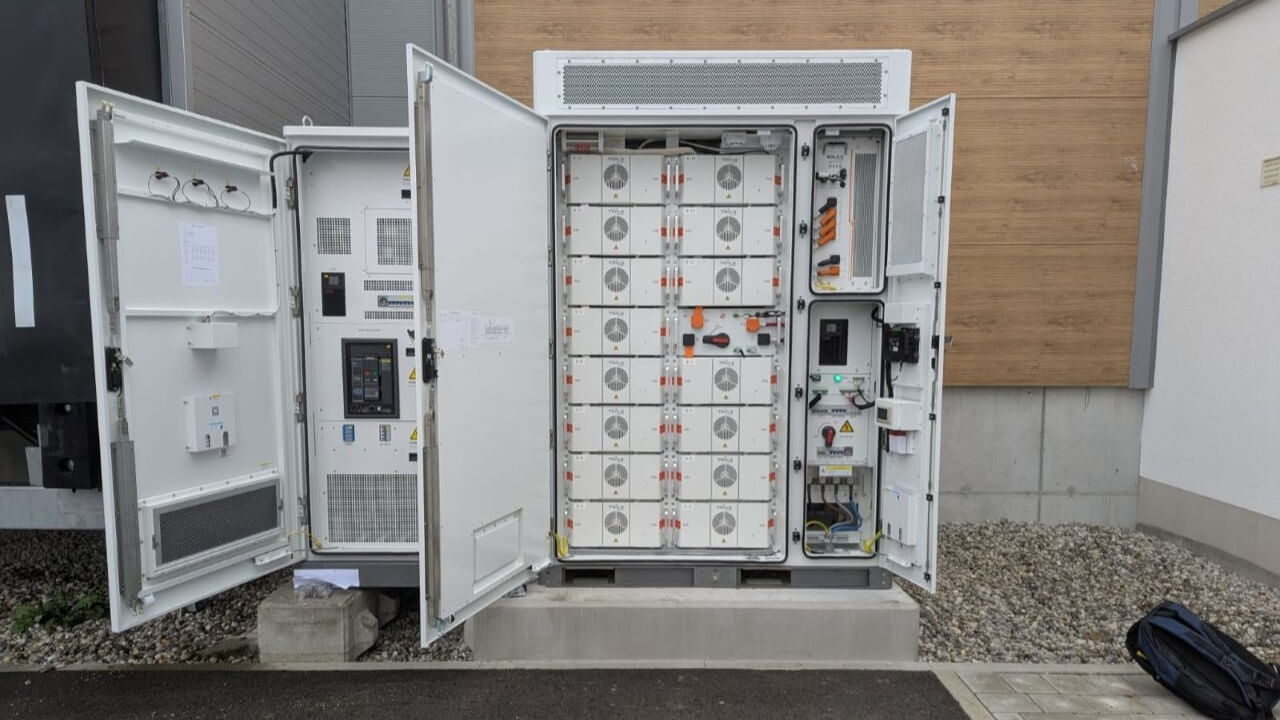

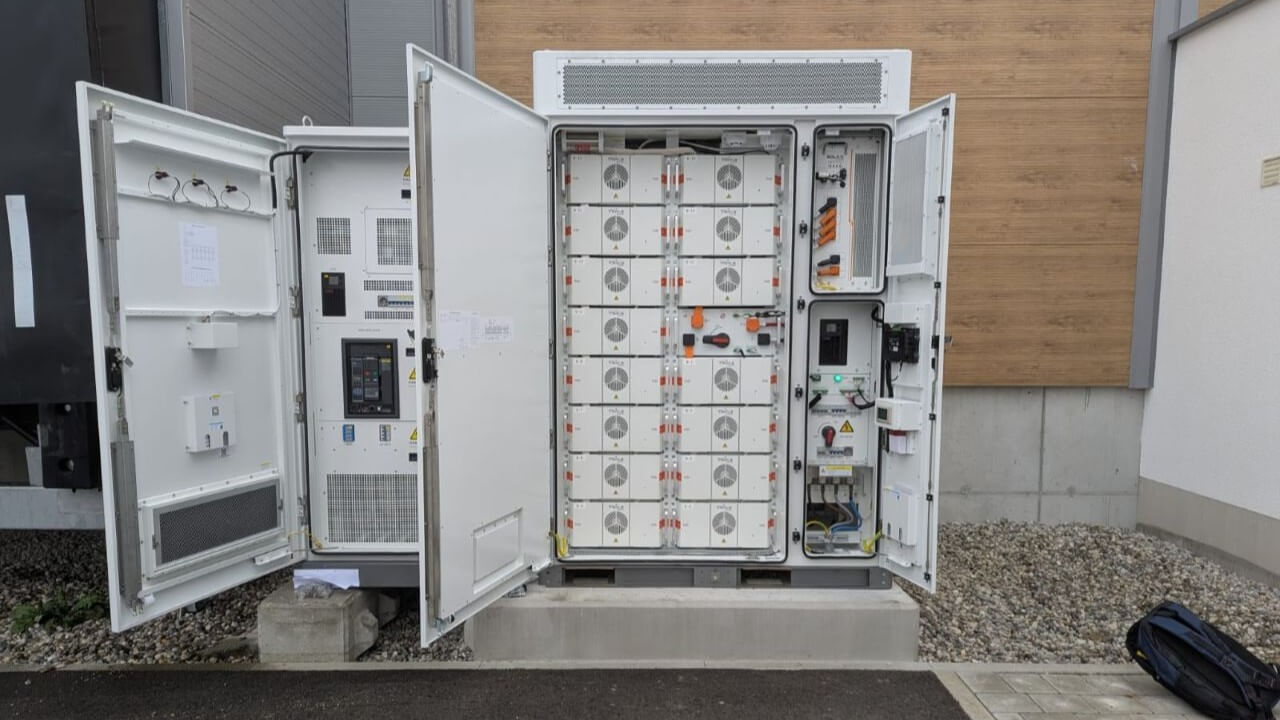

The platform highlights an all-in-one design integrating battery, PCS, thermal management, and AC/DC distribution.

It lists up to 261 kWh battery capacity and up to 125 kW power output for that cabinet class.

If you need concrete cabinet parameters to sanity-check space and logistics, one listed configuration includes:

LFP battery type with 314 Ah cells

261 kWh battery capacity

Rated battery voltage 832 V

Dimensions 1350 x 2355 x 1350 mm

Weight 2810 kg

Operating temperature range -30 to 55 C (derating above 45 C)

Max altitude 3000 m

For this step, focus on how an all-in-one ESS simplifies the system:

Fewer separate enclosures can reduce field wiring complexity.

Integrated thermal management supports stable performance.

A single engineered cabinet helps commissioning stay consistent.

Product Page: Commercial and Industrial All-in-One ESS

4 Select safety and enclosure ratings

Agricultural sites often include washdown areas, dust, and corrosive environments. Therefore, IP ratings and layered fire safety design matter as much as kWh.

For enclosure protection, verify:

Where the inverter and power electronics sit (inverter box location and ventilation).

Whether the cabinet is outdoors, semi-sheltered, or indoors.

Water jets, humidity, ammonia exposure (poultry), and dust (grain).

A SolaX C&I ESS safety highlight lists:

Four layers of fire safety protection

IP66 inverter protection rating

IP55 cabinet protection rating

That combination is useful for C&I sites that need durability while maintaining service access.

Also document your safety workflow. NFPA defines the electrically safe work condition concept used for energized work planning, which helps you structure lockout, verification, and commissioning checks.

Product Page: Commercial and Industrial All-in-One ESS

Scenario Variations Adapting Your Approach

Egg processing and cold-chain continuity focus:

Prioritize fast switching and stable frequency/voltage for refrigeration controls.

Keep a higher minimum SOC overnight because spoiled inventory costs more than missed arbitrage.

Dairy farms and milking load peak shaving:

Size for short high peaks from pumps and vacuum systems.

Use EMS demand limiting and pre-charge before milking windows to reduce grid spikes.

Irrigation pumps and daytime solar PV shifting:

Focus on matching PV output to pump run windows.

If pumps must run after sunset, increase kWh and plan staged pump starts.

Grain drying and seasonal demand management:

Build two schedules: in-season and off-season.

Plan for dust and filtration, and double-check enclosure placement and ventilation.

Troubleshooting Guide Common Problems and Solutions

Problem | Cause | Solution |

Unexpected demand charges after ESS install | EMS demand limit set too high or wrong peak window | Lower the demand limit in small steps, then validate against 15-minute utility demand intervals. Align discharge windows to the tariff peak definition. |

PV curtailment events during high solar output | Export limit or inverter controls restricting PV | Check export limit settings and CT polarity. Increase on-site consumption via scheduled charging or flexible loads during midday solar energy peaks. |

Backup fails during an outage | Switching device wiring, control logic, or critical panel mapping error | Re-test transfer with a staged load plan. Verify the emergency transfer switching device I/O mapping and confirm only critical circuits are connected. |

ESS runs out of energy before the end of the night | Minimum SOC set too low or critical loads underestimated | Raise backup reserve SOC and re-check the overnight kW profile. Consider shedding non-critical loads or adding cabinet capacity. |

Frequent alarms or derating on hot days | High ambient temperature or airflow/thermal constraints | Confirm clearance and cabinet placement. Adjust schedules to avoid long high-power discharge during the hottest hours and validate derating behavior. |

Conclusion

Choosing the top ESS for solar-powered agricultural applications is mostly about engineering discipline: define critical loads, size both kW and kWh, demand the right safety ratings, and verify fast backup switching. Then use monitoring to keep the system aligned with real operations.

A well-integrated solar energy storage system can stabilize cold-chain processes, reduce peak demand, and support a broader smart energy plan that may also include EV charging and future expansion. Once the system is live, keep tuning schedules monthly so the ESS keeps delivering reliable energy solutions.

FAQ

Table of Contents

Last News

Explore expert insights, practical guides, and the latest news on SolaX Power.

To the Latest Newsletter

Stay Ahead with the Latest SolaX Updates!

Subscribe

I have read and agree to Privacy Policy and User Terms